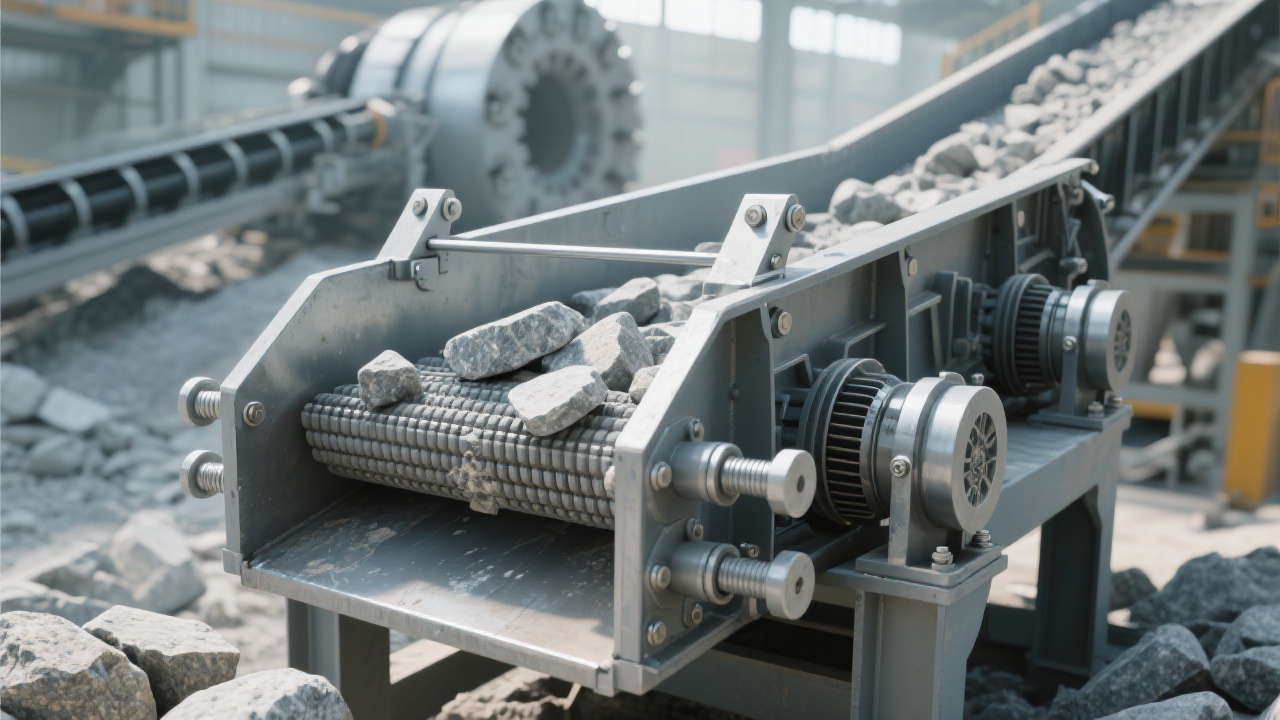

In the mining industry, the choice of crushing equipment significantly impacts production efficiency and cost. Recently, more and more mining enterprises are turning to the NK series mobile crushing stations. Let's delve into the reasons behind this trend and explore the practical applications of these stations.

Traditional crushing stations often come with complex installation processes and low transfer efficiency. For instance, setting up a traditional stationary crushing station can take weeks or even months, involving a large amount of concrete foundation work and equipment assembly. Moreover, once installed, it's difficult to move to a new location, which is a major drawback for mining operations that require frequent relocation.

However, the NK series mobile crushing stations offer a solution to these problems. With their modular design, they can be quickly installed and disassembled. In fact, the installation time of an NK series mobile crushing station is typically reduced by up to 70% compared to traditional stations. This means that mining enterprises can start production much faster and respond more quickly to changes in the mining site.

The NK series is equipped with a PLC touch - screen intelligent control system. This system allows operators to monitor and control the entire crushing process with ease. For example, they can adjust the crushing parameters such as the feeding speed and the crushing ratio in real - time, ensuring high - quality and efficient production. In addition, the system provides fault diagnosis and alarm functions, which can significantly reduce maintenance time and costs. According to some users' feedback, the maintenance efficiency has been improved by about 60% after using the intelligent control system.

The modular structure of the NK series mobile crushing stations not only enables quick installation but also offers flexibility. Different modules can be combined according to different production requirements, providing multi - purpose choices for mining enterprises. For example, if a mine needs to process different types of ores, it can easily adjust the configuration of the crushing station by changing or adding modules.

Eliminating the need for a concrete foundation is another major advantage of the NK series. This not only saves a large amount of construction time and cost but also reduces the environmental impact. Without the need for a large - scale concrete foundation, the mobile crushing station can be easily moved to different locations on the mining site, improving the overall production efficiency.

Let's take a look at some real - world examples. A mining company in Africa was facing low production efficiency and high costs with its traditional crushing station. After switching to the NK series mobile crushing station, the production capacity increased by 50%, and the operating cost was reduced by 30%. Another mining enterprise in South America was able to quickly adapt to the changing mining environment with the flexibility of the NK series, significantly enhancing its competitiveness in the market.

| Features | NK Series Mobile Crushing Stations | Traditional Crushing Stations |

|---|---|---|

| Installation Time | Reduced by up to 70% | Long (weeks or months) |

| Transfer Efficiency | High, easy to move | Low, difficult to move |

| Maintenance Cost | Reduced by about 60% with intelligent system | High |

| Production Capacity | Can increase by up to 50% | Relatively stable but limited |

In conclusion, the NK series mobile crushing stations offer significant advantages in terms of installation speed, transfer efficiency, intelligent control, and cost - effectiveness. They can help mining enterprises achieve higher production efficiency, lower costs, and greater flexibility. If you're in the mining industry, do you face similar problems as the enterprises mentioned above? Are you interested in learning more about how the NK series mobile crushing stations can solve your business pain points? Click here to get more information and 3 real - world solution cases from the same industry.