In the complex and demanding world of crushing production lines, the efficiency and stability of the feeding system directly impact the overall performance of the entire operation. Among the numerous feeding equipment options available, the ZSW Vibrating Feeder stands out as the perfect solution for high - efficiency feeding in crushing production lines. This article will comprehensively introduce its features, advantages, and practical applications to help you understand why it is an ideal choice for your crushing production needs.

One of the key functions of the ZSW Vibrating Feeder is its ability to provide continuous and uniform feeding to crushers. By using advanced vibration technology, it can precisely control the flow rate of materials, ensuring that the crusher receives a stable supply of materials. This not only improves the crushing efficiency but also reduces the wear and tear on the crusher, extending its service life.

In addition to feeding, the ZSW Vibrating Feeder also offers preliminary screening capabilities. It can separate small particles from large ones before the materials enter the crusher. This helps to reduce the workload of the crusher and improve the overall processing efficiency. For example, in a limestone crushing production line, the feeder can pre - screen out fine powder, allowing the crusher to focus on processing larger stones.

The ZSW Vibrating Feeder is suitable for a wide variety of materials, including limestone, granite, basalt, iron ore, and coal. Its input size ranges from 0 - 800mm, and it has a production capacity of 30 - 1000 TPH (tons per hour). These figures demonstrate its strong adaptability and high - performance capabilities, making it suitable for both small - scale and large - scale crushing production lines.

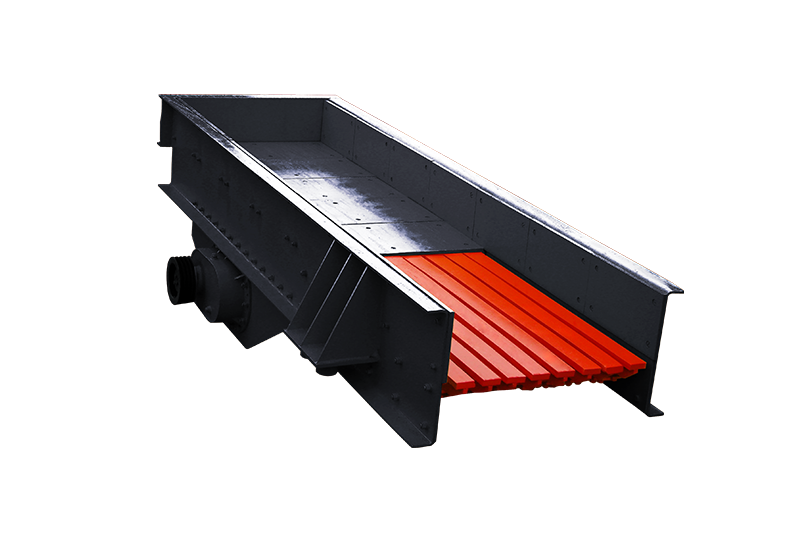

The ZSW Vibrating Feeder features a classic design and is equipped with a double - eccentric shaft vibration exciter. This design provides a stable and powerful vibration force, ensuring reliable operation even under heavy - load conditions. Moreover, the feeder operates with low noise and produces no pollution, which is in line with the trend of green mining. As environmental regulations become more stringent, this feature makes the ZSW Vibrating Feeder a more attractive option for mining and crushing enterprises.

Compared with other similar products on the market, the ZSW Vibrating Feeder has several distinct advantages. Firstly, its high - precision feeding control and preliminary screening function can significantly improve the efficiency of the entire crushing production line. Secondly, its low - maintenance design reduces downtime and maintenance costs. Finally, its compliance with environmental standards makes it a more sustainable choice for long - term operation.

Many customers around the world have benefited from using the ZSW Vibrating Feeder. For example, a large - scale mining company in Australia installed the ZSW Vibrating Feeder in its iron ore crushing production line. After using the feeder, the production efficiency increased by 30%, and the maintenance cost was reduced by 20%. This real - world example clearly demonstrates the value of the ZSW Vibrating Feeder in improving production efficiency and reducing costs.

In conclusion, the ZSW Vibrating Feeder is an indispensable part of modern crushing production lines. Its continuous and uniform feeding, preliminary screening function, wide applicability, unique design features, and significant comparative advantages make it an ideal choice for improving efficiency and reducing costs in crushing operations. If you are looking for a reliable and high - performance feeding solution for your crushing production line, don't hesitate to contact us. Our professional team will provide you with detailed product information and customized solutions to meet your specific needs. Click the button below to get in touch with us now!

Contact Us Now