In the realm of material handling, the challenges are as diverse as the materials themselves. Issues such as inconsistent feeding, low efficiency, and high maintenance costs have long plagued the industry. These problems not only affect the productivity of production lines but also increase operational costs for businesses. Enter the SP Series Vibrating Feeder, a revolutionary solution designed to address these long - standing pain points.

The development of the SP Series Vibrating Feeder is a testament to the company's commitment to innovation. By combining years of in - house R & D experience with the absorption of cutting - edge international technologies, the SP Series stands out as a leader in the field.

One of the most significant technological breakthroughs in the SP Series is the dual vibration motor drive technology. In this system, two vibration motors are arranged in a specific configuration. When the motors rotate, they generate a powerful and stable vibration force. The principle behind this is based on the synchronization of the two motors' rotation. As they rotate in opposite directions, the horizontal components of the centrifugal forces cancel each other out, while the vertical components are superimposed, resulting in a pure and effective vertical vibration.

This technology offers several advantages. Firstly, it provides a more uniform and stable feeding flow. Tests have shown that compared to traditional single - motor feeders, the SP Series can reduce the variation in feeding volume by up to 30%. Secondly, the dual - motor design distributes the load more evenly, which significantly extends the service life of the motors. In practical applications, the motors in the SP Series can operate continuously for over 10,000 hours without major failures, compared to around 6,000 hours for traditional models.

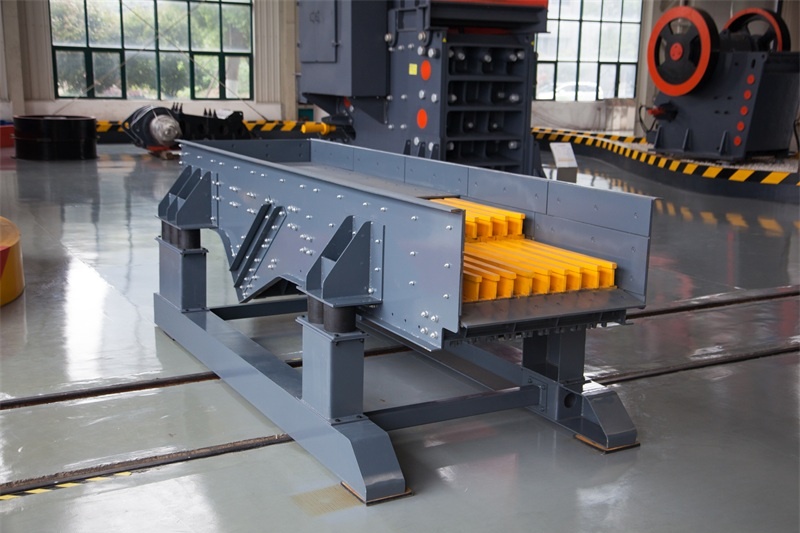

The advanced technology in the SP Series is closely reflected in its product features. The feeder has a high - strength and wear - resistant feeding trough. The vibration generated by the dual - motor system ensures that materials are transported smoothly along the trough without clogging. The feeder also has a flexible adjustment function. Users can easily adjust the feeding speed and volume by changing the vibration frequency and amplitude of the motors, which is crucial for different production requirements.

When compared with traditional feeders, the SP Series has several distinct technological advantages. Traditional feeders often rely on mechanical transmission systems, which are prone to mechanical wear and require frequent maintenance. In contrast, the SP Series uses a vibration - based feeding mechanism, which has fewer moving parts and thus lower maintenance requirements. Additionally, traditional feeders may have limitations in terms of feeding accuracy and stability, while the SP Series can achieve a feeding accuracy of up to ± 2%.

| Features | SP Series Vibrating Feeder | Traditional Feeder |

|---|---|---|

| Feeding Consistency | High (up to 30% more consistent) | Low |

| Motor Lifespan | Over 10,000 hours | Around 6,000 hours |

| Maintenance Requirements | Low | High |

| Feeding Accuracy | ± 2% | ± 5% |

Many companies in the material handling industry have already benefited from the SP Series Vibrating Feeder. For example, a mining company replaced its traditional feeders with the SP Series. After installation, they noticed a 25% increase in overall production efficiency and a 40% reduction in maintenance costs within the first year. Another food processing company reported a significant improvement in product quality due to the more accurate and consistent feeding provided by the SP Series.

The SP Series Vibrating Feeder offers a more stable and efficient material handling solution. Its advanced technology, combined with real - world performance data, makes it a reliable choice for businesses looking to upgrade their material handling systems. If you want to enhance your company's competitiveness and increase your market share, don't hesitate to contact us for more information about the SP Series Vibrating Feeder. Let us help you transform your material handling operations.