In the global mining and aggregate production industry, the efficiency and stability of crushing production lines are crucial. The ZSW Vibrating Feeder has emerged as a game - changer in foreign crushing production lines. For example, in a large - scale aggregate production project in Australia, the traditional feeding equipment often led to uneven feeding, which affected the overall production efficiency. After the introduction of the ZSW Vibrating Feeder, the situation was completely reversed.

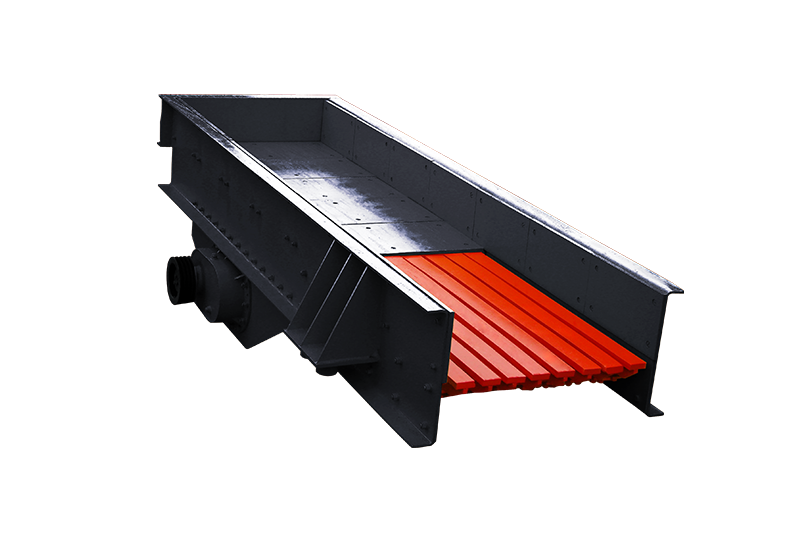

The ZSW Vibrating Feeder operates on the principle of vibration, which can continuously and uniformly feed materials into the crusher. This is achieved through its unique vibration motor design and adjustable amplitude. In a marble crushing plant in Italy, the ZSW Vibrating Feeder can maintain a feeding capacity of 200 - 300 tons per hour, ensuring a stable supply of materials to the crusher. Moreover, it has a preliminary screening function. The feeder is equipped with a screening plate at the discharge end, which can separate fine materials and large - sized materials. In a granite crushing project in Brazil, about 20% - 30% of fine materials can be pre - screened out, reducing the load on the crusher and improving the overall crushing efficiency.

The ZSW Vibrating Feeder is suitable for a wide range of materials, including granite, marble, limestone, basalt, and other hard and brittle materials. In a limestone quarry in Indonesia, the ZSW Vibrating Feeder has been used for a long - term and stable operation. It can handle materials with a maximum input size of up to 1000mm, which meets the feeding requirements of most crushing production lines. The output capacity can range from 80 tons per hour to 1000 tons per hour, which can be adjusted according to different production needs.

| Feature | Details |

|---|---|

| High - strength structure | The feeder is made of high - strength steel plates, which can withstand the impact of large - sized materials. For example, in a large - scale mining project in South Africa, the ZSW Vibrating Feeder has withstood the impact of large granite blocks without any structural damage. |

| Low energy consumption | Compared with traditional feeding equipment, the ZSW Vibrating Feeder can save about 15% - 20% of energy consumption. In a long - term operation, this can significantly reduce production costs. |

| Easy maintenance | The feeder has a simple structure and few wearing parts. In a small - scale aggregate production plant in Thailand, the maintenance staff can easily complete the daily maintenance work, reducing the downtime of the production line. |

Compared with other similar products on the market, the ZSW Vibrating Feeder has obvious advantages. Other products may have problems such as uneven feeding, low screening efficiency, and high energy consumption. However, the ZSW Vibrating Feeder can provide continuous and uniform feeding, high - efficiency preliminary screening, and low - energy operation. For example, in a side - by - side comparison test with a competitor's product in a European aggregate production plant, the ZSW Vibrating Feeder showed a 30% higher feeding stability and a 25% higher screening efficiency.

The ZSW Vibrating Feeder plays a vital role in crushing production lines. It can improve the overall production efficiency, reduce the wear and tear of the crusher, and save energy and production costs. In the context of the global trend of green mine development, the ZSW Vibrating Feeder's low - energy and high - efficiency features make it an ideal choice for sustainable development. It helps to reduce the environmental impact of mining and aggregate production. If you are looking for a reliable and efficient feeding solution for your crushing production line, the ZSW Vibrating Feeder is definitely the best option. Contact us now to learn more about how the ZSW Vibrating Feeder can transform your production line!