When it comes to optimizing the efficiency of crushing production lines, the ZSW Vibrating Feeder stands out as an indispensable piece of equipment. In the global market, where every second counts and cost - effectiveness is key, selecting the right feeder can make or break a project. Let's dive into why the ZSW Vibrating Feeder is a game - changer.

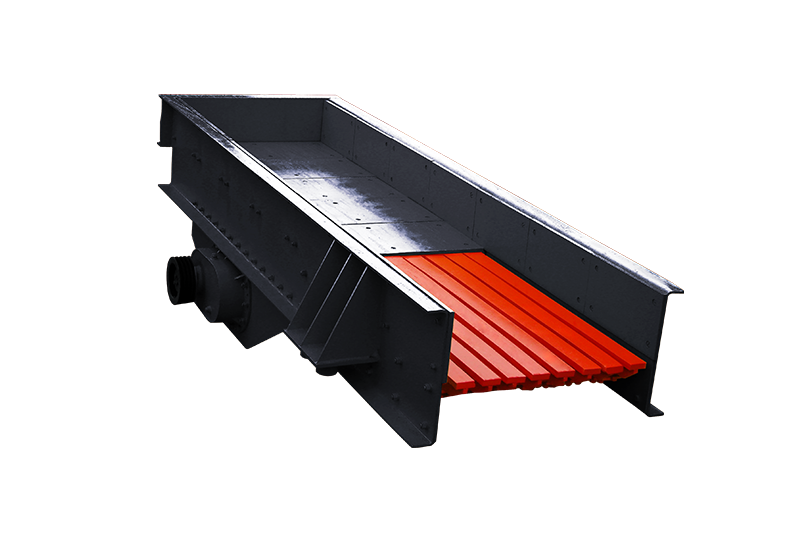

The ZSW Vibrating Feeder is engineered to provide a continuous and uniform flow of materials to crushers. This ability ensures that the crusher operates at its optimal capacity, reducing wear and tear and increasing overall output. Its unique design allows it to perform a preliminary screening function while feeding.

Materials with particle sizes within the range of 0 - 800mm can be processed. With a remarkable production capacity ranging from 30 to 1000 TPH (tons per hour), it can meet the demands of various large - scale and small - scale projects. Whether it's granite, limestone, or ore, this feeder can handle them all.

One of the hallmarks of the ZSW Vibrating Feeder is its classic design. It combines long - standing engineering wisdom with modern technological advancements. The double - eccentric shaft vibration exciter is a masterpiece of design, which generates a powerful and stable vibration force.

This not only facilitates the smooth movement of materials but also ensures low noise operation. Additionally, it operates with minimal pollution, adhering to the strict environmental standards of the green mining trend. This means that users can focus on production without worrying about environmental compliance.

Don't just take our word for it; the performance of the ZSW Vibrating Feeder has been well - proven in real - world applications. For instance, a large - scale mining project in Australia was facing challenges of uneven feeding and high energy consumption. After installing the ZSW Vibrating Feeder, they witnessed a 20% increase in crushing production line efficiency and a 15% reduction in energy costs.

Another client in South Africa, dealing with a complex mix of materials, reported a significant improvement in product quality after using the ZSW Vibrating Feeder. The precise preliminary screening reduced the burden on subsequent processes, resulting in a more streamlined operation.

Compared with other similar products on the market, the ZSW Vibrating Feeder stands out. Some competing models may offer only basic feeding functions without effective preliminary screening, leading to over - work of crushers. Others may generate excessive noise and pollution, causing significant environmental concerns and additional management costs.

In contrast, the ZSW Vibrating Feeder's combination of multi - functionality, low - noise operation, and environmental friendliness gives it a clear edge. Its reliability and high performance ensure a quick return on investment for users.

In conclusion, the ZSW Vibrating Feeder is an ideal choice for anyone looking to enhance the efficiency of their crushing production lines. It not only improves productivity and product quality but also reduces operating costs and environmental impact. If you are still on the fence about your next equipment purchase, seizing this opportunity to integrate the ZSW Vibrating Feeder into your production line could be the most profitable decision you make this year.

Contact us now to learn more about how the ZSW Vibrating Feeder can transform your crushing operation! Let's work together to achieve higher efficiency and greater profitability.