Efficient material feeding remains a pivotal challenge in industries such as marble quarrying, granite processing, and mining operations. Traditional inertial feeders often struggle with inconsistent feed rates, bulky designs, and difficult maintenance, which directly impact production throughput. Enter the SP Series High-Intensity Vibrating Feeder, a solution engineered to deliver stable, uniform material feed across diverse scenarios, streamlining operational workflows and boosting productivity.

The SP Series feeder excels in handling heavy, abrasive materials such as marble blocks, granite stones, and raw minerals. Industries commonly face challenges including frequent equipment downtime, uneven feeding that disrupts downstream processing, and inflexible installation setups that complicate workflow layouts. These pain points often lead to reduced operational efficiency and elevated costs.

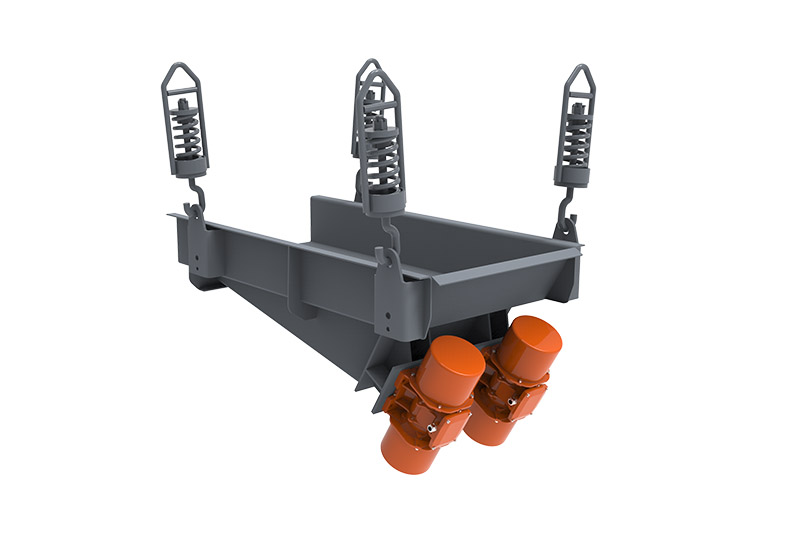

Designed with a compact structure, the SP Series feeder is notably easier to integrate within limited space environments. Its flexible installation options adapt seamlessly to existing production lines, significantly reducing setup time. The high-frequency vibrating mechanism ensures an evenly distributed feed, stabilizing material flow and preventing bottlenecks.

Compared to conventional GZG and GZD feeders, the SP Series delivers a feed capacity improvement of up to 30%, underpinning its superior performance. Its robust construction minimizes wear, lowering maintenance intervals by up to 25%, translating to substantial downtime reduction.

“Since switching to the SP Series feeder, our marble processing line has seen a remarkable 28% increase in throughput. The uniform feed has minimized material spillage and machine clogging, allowing us to meet tighter delivery schedules efficiently.” – Production Manager, Leading Granite Quarry

One of the top-tier granite suppliers in Southeast Asia integrated SP Series feeders across three production facilities. Their results showed an average operational efficiency gain of 30% within six months. This improvement was primarily driven by stabilized material flow, reduced mechanical failures, and simplified maintenance protocols.

Crafted by Zhengzhou Mining Machinery, a trailblazer in mining equipment innovation, the SP Series benefits from decades of R&D and hands-on industry feedback. With service coverage spanning over 137 countries, the brand assures reliable support and rapid after-sales service, ensuring equipment uptime and customer confidence worldwide.

| Feature | Benefit | Performance Metrics |

|---|---|---|

| Compact Design | Easy integration into existing lines | Installation time reduced by 20% |

| Uniform Feeding | Minimizes interruptions and material wastage | Feed rate consistency within ±5% |

| Durability | Lower maintenance, longer lifespan | Maintenance frequency down 25% |

Have you encountered challenges with your current feeding systems? How do you ensure consistent material flow in your operations? Share your experiences below and join the conversation to discover practical solutions.

The SP Series is engineered not just for immediate productivity gains but also for sustainable operational growth. Its combination of smart design, proven reliability, and global backing offers industrial operators worldwide a decisive edge.