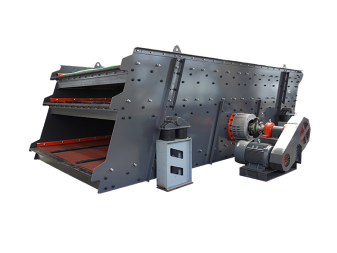

The S5X vibrating screen is a high - performance screening device developed by Zhengzhou Mining Alliance Machinery Co., Ltd. It has a maximum feed size of 200 millimeters and a processing capacity ranging from 45 to 900 tons per hour. This makes it suitable for a wide range of materials, including granite, limestone, and other common minerals, which are widely used in the mining and construction industries.

Compared with traditional screening equipment, the S5X vibrating screen has a significantly higher vibration intensity. Traditional screens usually have a vibration intensity of around 3 - 4g, while the S5X can reach up to 7g. This high - intensity vibration allows materials to move more quickly on the screen surface, reducing the probability of blockage and improving the overall screening efficiency.

The processing capacity of the S5X vibrating screen is also a major advantage. Traditional screening equipment may only process 20 - 300 tons per hour, depending on the model. In contrast, the S5X can handle up to 900 tons per hour. This large - scale processing ability makes it ideal for large - scale mining and construction projects.

The S5X vibrating screen achieves a screening efficiency of up to 90%, while traditional screens typically have an efficiency of 60 - 70%. The high - efficiency screening of the S5X ensures that more qualified products are obtained in a shorter time, which is crucial for industries where time is money.

The S5X is equipped with a more powerful vibration exciter, which can generate a stable and strong vibration force. This exciter is designed with advanced technology to ensure long - term reliable operation.

The screen box structure of the S5X has been optimized. It uses a modular design, which is convenient for installation, maintenance, and replacement of parts. The box is also designed to withstand high - intensity vibrations, ensuring its durability.

The transmission mode of the S5X vibrating screen is designed to be more efficient. It can effectively transfer the vibration force to the screen surface, making the screening process more stable and efficient.

The S5X vibrating screen uses rubber springs as elastic support components and SV super - energy exciters. The rubber springs can effectively absorb vibration and shock, reducing the impact on the foundation and surrounding environment. This results in a more stable operation, lower noise levels (usually below 75 decibels), and a longer service life. The SV super - energy exciters provide a high - energy and stable vibration source, ensuring the high - efficiency operation of the screening process.

Zhengzhou Mining Alliance Machinery Co., Ltd. has significant advantages in parts processing. It uses high - precision machining equipment to ensure the accuracy and quality of each part. The company also provides a complete set of spare parts supply services, ensuring that customers can quickly obtain the required parts when needed. In addition, the company offers professional technical support, including installation guidance, maintenance training, and troubleshooting services.

In a large - scale granite mining project in Africa, the customer originally used traditional screening equipment, which had low efficiency and frequent breakdowns. After switching to the S5X vibrating screen, the processing capacity increased by 150%, and the screening efficiency improved from 65% to 85%. This not only reduced the production cost but also significantly increased the output of qualified products.

In conclusion, the S5X vibrating screen is the ideal choice for customers aiming for high - efficiency production. With the comprehensive services provided by Zhengzhou Mining Alliance Machinery Co., Ltd., customers can operate the equipment without worries. If you are looking for a reliable and high - performance screening solution, don't hesitate to contact us now!