In the modern industrial landscape, the efficiency of material handling is a critical factor that directly impacts productivity and profitability. The current material conveying industry is grappling with several efficiency - related issues. Traditional feeding equipment often suffers from low throughput, uneven material distribution, and high energy consumption. These problems not only lead to increased production costs but also limit the overall capacity of production lines. This is where the GF Vibrating Feeder steps in, poised to revolutionize the way materials are transported.

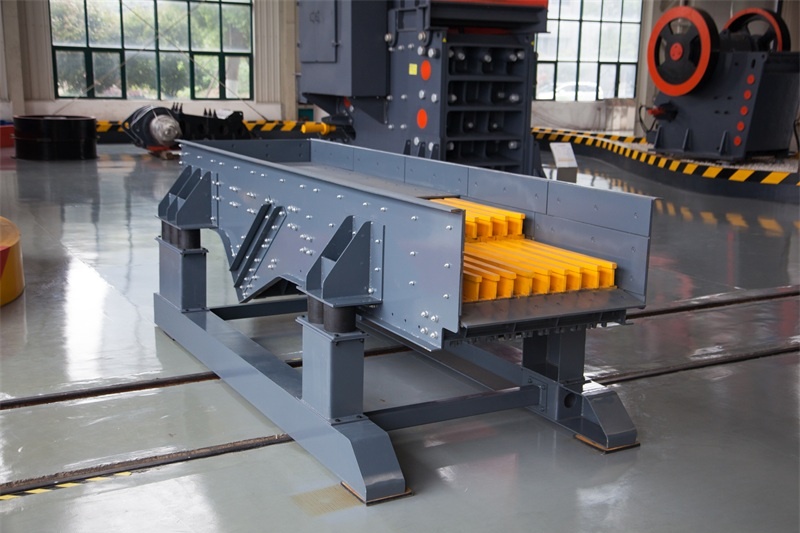

The GF Vibrating Feeder is a high - efficiency primary feeding device with a wide range of remarkable features. In terms of applicable scenarios, it can be used in various settings such as mobile crushing stations, semi - fixed crushing production lines, and small silos. It can handle a variety of materials, including granite, limestone, and basalt, making it a versatile choice for different industries.

When it comes to work efficiency, the GF Vibrating Feeder stands out. It has a large feeding size, capable of handling materials up to 800mm in diameter. Its processing capacity is also impressive, with a maximum throughput of up to 1000 tons per hour. These figures far exceed those of many traditional feeding devices, ensuring a smooth and continuous flow of materials in the production process.

Let's take a look at a data comparison to further illustrate the advantages of the GF Vibrating Feeder. Compared with a conventional vibrating feeder, the GF model can increase the feeding efficiency by 30%. In terms of energy consumption, it consumes 20% less electricity under the same working conditions. These data clearly show that the GF Vibrating Feeder not only improves productivity but also helps to save energy and reduce costs.

One of the key strengths of the GF Vibrating Feeder is its ability to adapt to multiple scenarios. Whether it is a large - scale mobile crushing operation or a small - scale silo feeding task, the GF Vibrating Feeder can perform excellently. Its adjustable vibration parameters allow it to be customized according to different material characteristics and production requirements, ensuring optimal performance in various environments.

The GF Vibrating Feeder uses a high - performance vibration motor as its vibration source. This vibration motor has several technical advantages. Firstly, it provides a stable and powerful vibration force, which ensures uniform material flow. Secondly, it has a long service life and low maintenance requirements, reducing the overall operating costs. The advanced design of the vibration motor also makes the feeder more reliable and durable, even in harsh working environments.

To further prove its value, let's look at a real - world customer case. A mining company in Australia was facing low efficiency in its crushing production line due to the poor performance of the original feeding equipment. After replacing it with the GF Vibrating Feeder, the company saw a significant improvement in production efficiency. The feeding process became more stable, and the overall throughput of the production line increased by 25%. This not only improved the company's productivity but also enhanced its competitiveness in the market.

In conclusion, the GF Vibrating Feeder is a game - changer in the material handling industry. With its high efficiency, multi - scenario adaptability, and advanced technical features, it is well - positioned to open a new era of efficient material conveying. If you are in the decision - making stage of choosing a feeding device, we encourage you to learn more about the GF Vibrating Feeder. You can contact our sales team at [contact email] or call [contact phone number] for more information. We also offer a free trial service to let you experience the excellent performance of our product firsthand. Don't miss this opportunity to improve your production efficiency and reduce costs.