In the current global material handling industry, efficiency has always been a core concern for businesses. Outdated feeding equipment often leads to problems such as uneven material supply, low processing capacity, and high energy consumption, which directly affect the overall productivity and profitability of the production line. However, the emergence of the GF Vibrating Feeder is set to change this situation and open a new era of high - efficiency material handling.

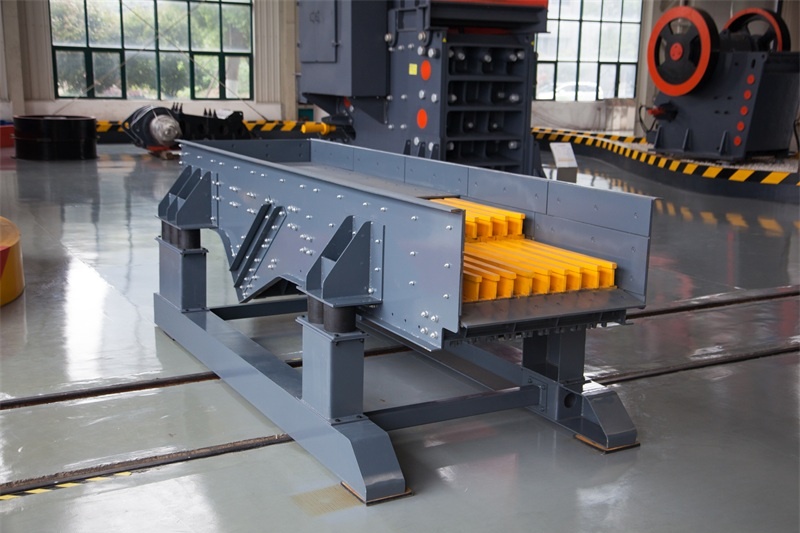

The GF Vibrating Feeder is a revolutionary product specifically designed for mobile crushing stations, semi - fixed crushing production lines, and small silos. Its unique design and advanced technology make it an ideal choice for various material handling scenarios.

With an impressive feed size of up to 700 millimeters, the GF Vibrating Feeder can handle large - sized materials with ease. Its high - capacity design allows it to process materials at a rate of 280 - 450 tons per hour, ensuring a continuous and stable supply of materials to the crushing equipment.

This feeder is suitable for a wide range of stone materials, including granite, limestone, basalt, and more. Whether in the mining, construction, or recycling industries, the GF Vibrating Feeder can adapt to different working environments and material characteristics, providing reliable performance.

Compared with traditional feeding equipment, the GF Vibrating Feeder shows significant advantages in terms of efficiency. Traditional feeders usually have a lower processing capacity, often ranging from 100 - 200 tons per hour, and are prone to blockages when dealing with large - sized materials. In contrast, the GF Vibrating Feeder's high - frequency vibration technology ensures smooth material flow, reducing downtime and increasing overall productivity.

The GF Vibrating Feeder's flexibility is one of its key selling points. In mobile crushing stations, its compact design and easy installation make it convenient for on - site operations. For semi - fixed crushing production lines, it can be integrated seamlessly into the existing system, improving the overall efficiency of the production line. In small silos, it can accurately control the feeding volume, ensuring the stability of the subsequent processes.

The GF Vibrating Feeder uses a high - performance vibration motor as its vibration source. This motor provides stable and adjustable vibration force, which can be adjusted according to different material characteristics and production requirements. The vibration frequency can be adjusted within a certain range, ensuring the best feeding effect for different materials.

Many customers around the world have already benefited from the GF Vibrating Feeder. For example, a mining company in Africa installed the GF Vibrating Feeder in its mobile crushing station. After using the feeder, the production efficiency increased by 30%, and the equipment downtime was significantly reduced. Another construction company in Europe used the feeder in its semi - fixed crushing production line, and the overall production capacity increased by 25%, bringing higher economic benefits.

Don't miss out on this high - efficiency primary feeding equipment! If you're looking to improve the efficiency of your material handling process, the GF Vibrating Feeder is the perfect solution. Contact us today to learn more about this amazing product and how it can transform your production line.