In the mining and related industries, the current crushing operations are facing a series of challenges. Inefficiency is a primary issue, with traditional crushers often struggling to meet the high - volume production demands. High energy consumption not only increases operating costs but also goes against the growing trend of environmental protection. Moreover, difficult maintenance can lead to long downtime, affecting the overall productivity of the enterprise. For example, in some small - scale mines, the average energy consumption per ton of ore crushing can be as high as 20 - 30 kWh, and the maintenance time can account for up to 20% of the total production time.

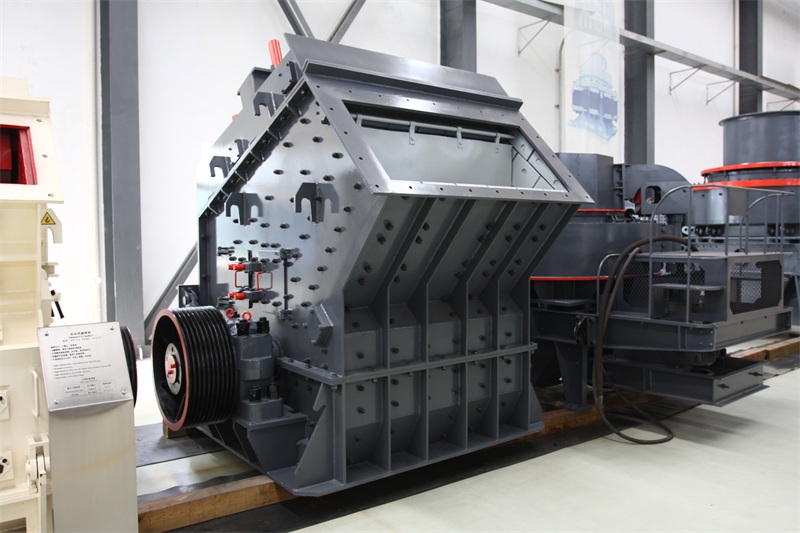

The PFW impact crusher stands out with its intelligent control system. This system can automatically adjust the crushing parameters according to the characteristics of the incoming ore, such as hardness and particle size. As a result, the crushing efficiency is significantly improved. The energy - saving design is another key highlight. By optimizing the crushing chamber structure and the movement trajectory of the rotor, the PFW crusher can reduce energy consumption by up to 30% compared with traditional models. For example, in a continuous crushing operation, the PFW crusher can maintain a stable power consumption level of about 15 kWh per ton of ore, which is a remarkable achievement in the industry.

In the metallurgical industry, the PFW crusher can effectively crush various ores, such as iron ore and copper ore. Its high - precision crushing ability ensures that the particle size of the crushed ore meets the requirements of subsequent smelting processes. This helps to improve the metal recovery rate and reduce the production cost.

In cement production, the PFW crusher is capable of processing limestone and other raw materials. The uniform particle size of the crushed materials can improve the quality of cement clinker and enhance the overall production efficiency of the cement plant.

For highway construction, the PFW crusher can produce high - quality aggregates. The shape of the aggregates is more regular, which is beneficial for improving the strength and durability of the asphalt mixture and concrete used in highway construction.

The PFW crusher uses a double - wedge type discharge opening adjustment system, while traditional models often use a bottom - plate type adjustment system. The double - wedge type system allows for more precise and flexible adjustment of the discharge opening size. This means that the PFW crusher can quickly adapt to different production requirements, and its production efficiency can be increased by about 20% compared with traditional models. In addition, the maintenance of the double - wedge type system is also more convenient, reducing the maintenance time and cost.

A large - scale mining enterprise decided to introduce the PFW impact crusher to upgrade its crushing production line. After a period of operation, remarkable results were achieved. The production output increased by 25%, which means that the enterprise can process more ore within the same time frame. At the same time, the operation and maintenance cost decreased by 30%. As the customer said in a feedback quote, 'The PFW crusher has completely changed our production situation. It not only improves our productivity but also saves a lot of costs. It's truly a game - changer for our business.'

In conclusion, the PFW impact crusher, with its innovative technologies, is a powerful tool for enterprises in the mining and related industries. It can effectively solve the industry pain points, improve production efficiency, and reduce costs. Technology innovation drives the sustainable development of enterprises and creates long - term competitive advantages. Let every ore achieve its maximum value - that's the change brought by the PFW impact crusher!