In today's dynamic mining and aggregate industries, one-size-fits-all crushing solutions no longer meet the demands of diverse production lines. You need a crushing system that adapts seamlessly to both hard-rock and soft-material environments, maximizing throughput while minimizing downtime.

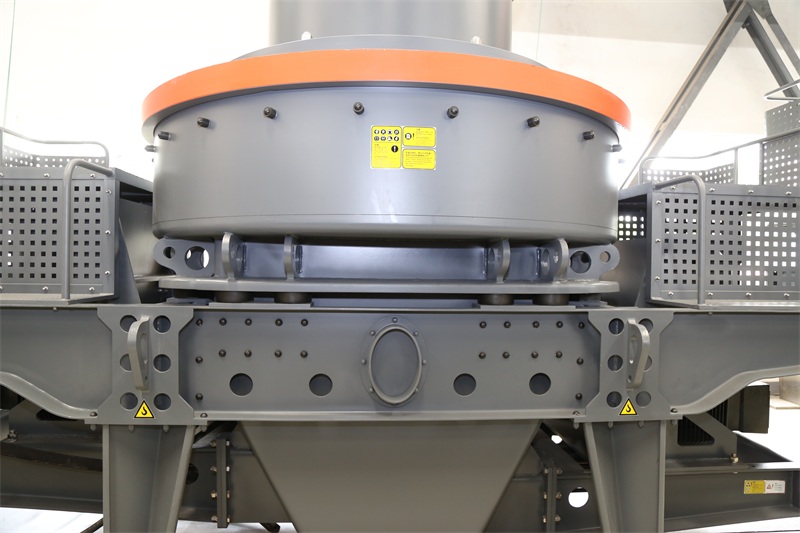

The PF Series High-Efficiency Impact Crusher offers precisely that flexibility. Its innovative design and adjustable parameters enable you to tailor the crushing process to your unique production requirements — empowering you to reduce wear and tear costs and optimize particle size distribution effortlessly.

Many production managers face issues such as rapid wear of crusher parts, inconsistent product size, and inefficient crushing cycles that slow overall output. These challenges lead to increased maintenance expenses and unexpected downtime, affecting your bottom line.

We understand these pain points intimately and designed the PF impact crusher to overcome them:

The adaptability of the PF crusher shines in handling varied materials:

The PF crusher lets you adjust several key parameters, including rotor speed, impact plate angle, and feed size, to suit the specific demands of your material and production goal. This level of customization means:

"Since switching to the PF impact crusher with customized settings, our plant increased output by 20% while cutting maintenance costs by nearly 18%. The flexible design perfectly handles both our granite and limestone materials without compromise." – Martin G., Operations Manager

Consider a quarry operating in a mixed deposit environment with alternating hard basalt and softer sandstone. By employing the PF crusher’s adjustable crushing profiles, they achieved a notable:

Don't settle for generic crushing solutions that underperform. The PF Series High-Efficiency Impact Crusher is engineered to adapt to your unique production landscape, providing the durability, flexibility, and efficiency your operations demand.

Click below to discover the perfect crushing solution tailored just for your production line.