In the granite processing industry, the feeding stage is a critical bottleneck that significantly impacts the overall productivity and reliability of the crushing production line. Efficient and stable feeding ensures a continuous supply of raw materials to the crushers, which is essential for maintaining high - throughput operations. However, traditional feeding methods often struggle to handle the large - sized and high - volume granite materials, leading to issues such as uneven feeding, equipment wear, and inconsistent crushing results.

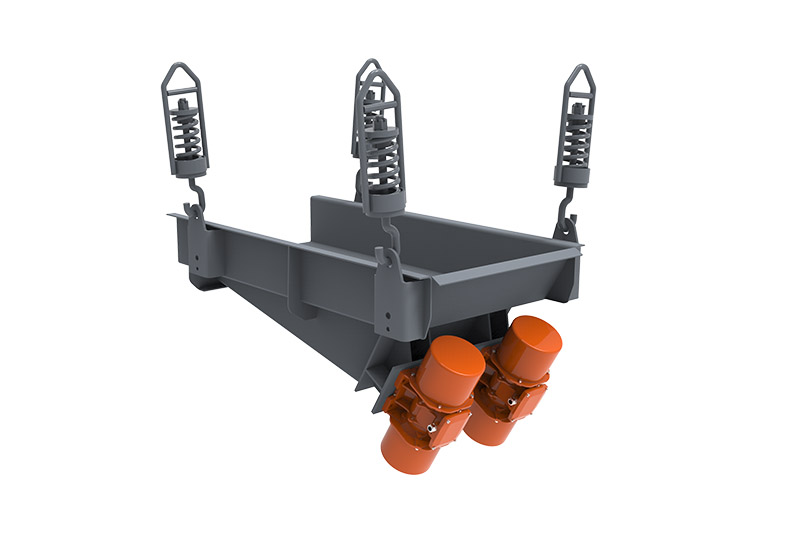

The GF vibrating feeder features an impressive 700mm large feed size, allowing it to accommodate large chunks of granite directly. With a handling capacity ranging from 280 to 450 tons per hour, it can meet the demands of various production scales. This high - capacity performance ensures a continuous and smooth supply of materials to the subsequent crushing processes.

One of the standout features of the GF vibrating feeder is its double - layer screening structure. This design enables pre - screening of the incoming granite materials, effectively separating the fine particles from the larger ones. As a result, the pre - screening efficiency is increased by approximately 20%, reducing the load on the crushers and improving the overall crushing efficiency.

The rubber spring damping design of the GF vibrating feeder plays a crucial role in reducing vibration and noise during operation. It also helps to extend the service life of the equipment by minimizing the impact on the feeder's components, thereby reducing maintenance costs and downtime.

The GF vibrating feeder is equipped with an advanced exciting force adjustment mechanism. This mechanism allows for precise control of the material conveying speed and flow rate. By adjusting the exciting force, operators can ensure a stable and uniform feed of granite materials to the crushers, optimizing the crushing process and reducing equipment wear. For example, in a high - volume production scenario, the exciting force can be increased to enhance the conveying capacity, while in a more delicate operation, it can be reduced for more precise control.

Let's take a look at some real - world customer cases to understand the adaptability and economic benefits of the GF vibrating feeder in different production scenarios. In a medium - sized granite processing plant, the installation of the GF vibrating feeder led to a 15% increase in overall production capacity and a 10% reduction in equipment maintenance costs within the first six months. In a large - scale mobile crushing station project, the feeder's ability to handle large - sized materials and its stable performance significantly improved the project's efficiency and reduced the operating costs.

The GF vibrating feeder offers long - term stability in operation. Its robust design and high - quality components ensure reliable performance even under harsh working conditions. The easy - to - maintain structure allows for quick and simple maintenance, reducing downtime and ensuring continuous production. In terms of return on investment, the improved productivity, reduced maintenance costs, and optimized crushing process make it a cost - effective solution for granite processing enterprises.

To better understand the working principle and application logic of the GF vibrating feeder, refer to the following flowchart (Figure 3). The flowchart illustrates how the feeder receives the granite materials, pre - screens them through the double - layer structure, and then conveys them to the crushers with precise control of the exciting force. This visual representation enhances the professional credibility of the product.

| Question | Answer |

|---|---|

| Can the GF vibrating feeder be used in mobile crushing stations? | Yes, it is suitable for both mobile crushing stations and semi - fixed production lines, providing flexible and reliable feeding solutions. |

| How much can the pre - screening efficiency be improved? | The pre - screening efficiency can be increased by approximately 20% due to the double - layer screening structure. |

Discover the Industry - Preferred GF Vibrating Feeder for Your Granite Processing Needs!