In today's fast-evolving mining industry, maximizing production efficiency while controlling operational costs has never been more critical. MiningAlliance’s NK Series mobile crushing stations have emerged as a transformative solution, combining cutting-edge modular design and intelligent control systems. This article explores how decision-makers can evaluate the economic benefits and flexibility of NK Series equipment to achieve optimal business outcomes.

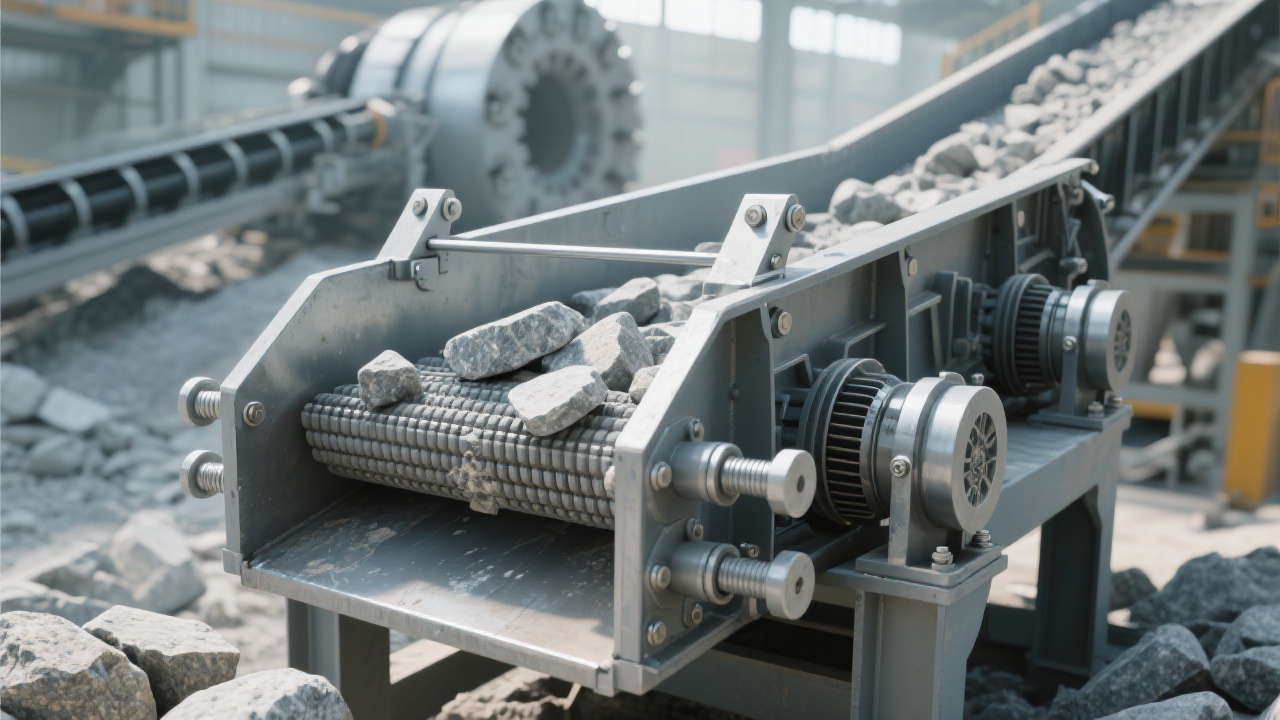

The NK Series mobile crushing station exemplifies adaptive engineering through its modular construction. Unlike traditional stationary crushers, NK units can be quickly assembled, disassembled, and relocated to different sites, significantly reducing downtime. Their scalable configurations allow customization to meet varied production volumes and material types.

For example, a copper mine in Chile leveraged NK Series flexibility to switch between crushing ore and overburden materials within hours, minimizing production interruptions and maximizing resource utilization.

| Performance Metric | NK Series | Conventional Stationary Crushers |

|---|---|---|

| Installation Cost Reduction | Up to 40% | Baseline |

| Average Downtime for Relocation | Less than 12 hours | 3-5 days |

| Production Capacity Increase | 15-25% | Baseline |

| Maintenance Efficiency Improvement | Up to 30% | Baseline |

These figures stem from a multi-site deployment by a major mining company, which demonstrated that the NK Series mobile crushing stations lowered installation costs by approximately 40%, eliminated days-long delays in relocation downtime, and boosted overall production capacities by up to 25%.

At the heart of the NK Series’ operational edge lies an advanced intelligent control system. This system enables real-time monitoring, automated adjustments, and predictive maintenance alerts, minimizing human error and optimizing machine uptime. Operators can remotely control crushing parameters via intuitive interfaces, reducing labor costs and training time.

A mining operator in Australia reported a 25% reduction in unplanned stoppages after integrating the NK Series’ smart control features, underscoring the system’s critical role in improving maintenance efficiency and lowering costs.

We invite industry peers to share specific pain points encountered during equipment procurement and production ramp-up. How do you balance cost considerations with operational flexibility in your crushing operations?

When benchmarked against conventional mobile and fixed crushing stations, the NK Series stands out in key areas:

Collectively, these advantages empower enterprises to dynamically respond to market demands and geological variances without compromising output or quality.

A multinational mining firm operating sites across diverse terrains in Africa adopted the NK Series to enhance operational agility. Through modular units, they achieved site-to-site relocation in under 12 hours, compared to the prior 4-day average. This agility minimized logistic overhead and allowed rapid responses to fluctuating resource availability.

Additionally, the firm noted a 20% increase in throughput per shift, attributed to the NK Series’ optimized crushing algorithms and stable mechanical performance.

Frequent unplanned stoppages can severely impact project timelines. The NK Series addresses this with predictive maintenance tools embedded in its intelligent control system, enabling early fault detection and streamlined service scheduling. Over time, this results in reduced maintenance costs and a higher mean time between failures (MTBF).

A mining operator in Canada reported cutting maintenance man-hours by nearly 30% within the first 6 months of NK Series deployment, contributing to overall operational efficiency.

Choosing the right mobile crushing equipment demands a thorough assessment of both economic returns and operational flexibility. MiningAlliance’s NK Series delivers on both fronts, offering modular adaptability, cost-effective deployment, and smart technologies designed for modern mining challenges. Industries aiming to elevate productivity and lower cost per ton should consider these innovative stations as pivotal assets.