In mining operations, the challenge of efficiently breaking down ore impacts both production yield and operational costs. Traditional impact crushers often lag behind in delivering optimal crushing ratios and face high maintenance expenses. Enter the PF series high-efficiency impact crushers, engineered to transform your ore processing with superior wear-resistant materials and innovative structural design. This article examines how PF impact crushers increase crushing efficiency, ensure product uniformity, and reduce downtime—empowering mining businesses worldwide.

Ore crushing traditionally involves equipment that struggles with low crushing ratios, inconsistent particle sizes, and frequent wear-and-tear—leading to costly maintenance. Many operations report crushing ratios below 1:10 and particle size distribution often requiring secondary processing, which increases energy consumption and labor costs.

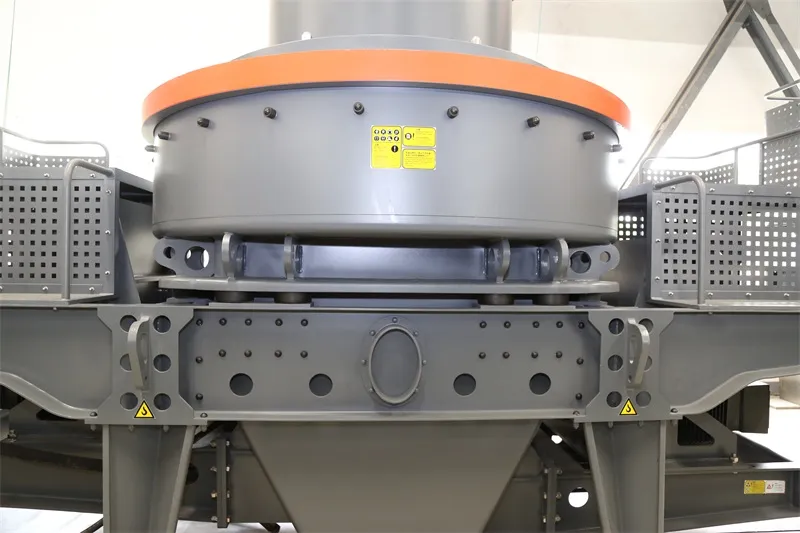

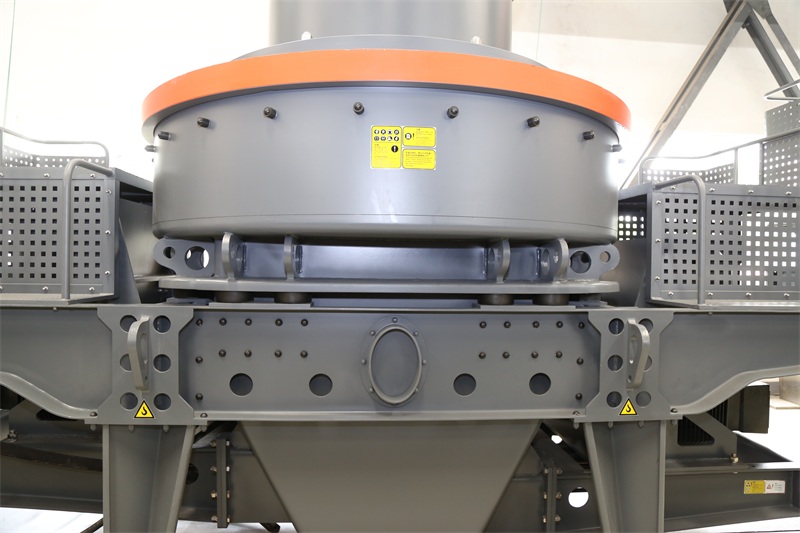

PF series crushers are designed using advanced wear-resistant materials and optimized geometry. These innovations yield remarkable performance:

| Performance Metrics | Traditional Crushers | PF High-Efficiency Crushers |

|---|---|---|

| Crushing Ratio | 1:8 — 1:10 | Up to 1:20 |

| Particle Size Uniformity | ~75% | ≥95% |

| Operational Downtime (%) | 15-20% | Less than 10% |

These improvements translate into more stable plant operation and increased throughput with less frequent downtime.

The PF impact crusher is engineered for flexibility—effectively processing materials ranging from hard rocks like basalt and granite to softer ores. This versatility is due to its custom-configurable impact bars and chamber designs, enabling smooth transitions between different crushing scenarios without compromising efficiency.

Understanding that no two mining operations are identical, PF crushers provide customizable configurations. Adjustments can be made on rotor speed, feed opening size, and wear-resistant plate thickness to meet specific crushing needs:

“Since upgrading to the PF high-efficiency impact crusher, our processing plant has seen a 30% boost in ore throughput and a 40% reduction in downtime and maintenance costs. The uniformity of crushed particles has also simplified our downstream processing, improving overall productivity.” — Mining Operations Manager, XYZ Minerals

PF crushers' enhanced crushing ratio and product consistency allow mines to process more ore per hour with less energy consumption, directly reducing operational expenses. Further economic benefits include:

Whether your operation entails hard rock extraction or softer material processing, the PF high-efficiency impact crusher presents a proven solution to elevate your crushing processes. Don’t let outdated equipment limit your productivity—