In the fast-paced world of aggregate and mining production, time equals money—and downtime is the silent killer of profitability. That’s why companies across Europe, Southeast Asia, and Latin America are turning to NK Series modular mobile crushers for their ability to reduce installation time by up to 60% compared to traditional setups.

A Brazilian quarry operator faced a critical challenge: they needed to shift operations from Site A to Site B within just 7 days due to land-use changes. Using conventional fixed crushing units would have meant weeks of disassembly, transport, and reinstallation—costing over $50,000 in labor alone.

Instead, they deployed an NK Series mobile crusher with fully modular components. The team assembled the unit on-site in under 48 hours using only two technicians. By leveraging pre-engineered connectors and integrated hydraulic systems, they achieved:

This wasn’t just about speed—it was about operational resilience. As one project manager said: “We now treat our mobile crusher like a Swiss Army knife: deployable, adaptable, and always ready.”

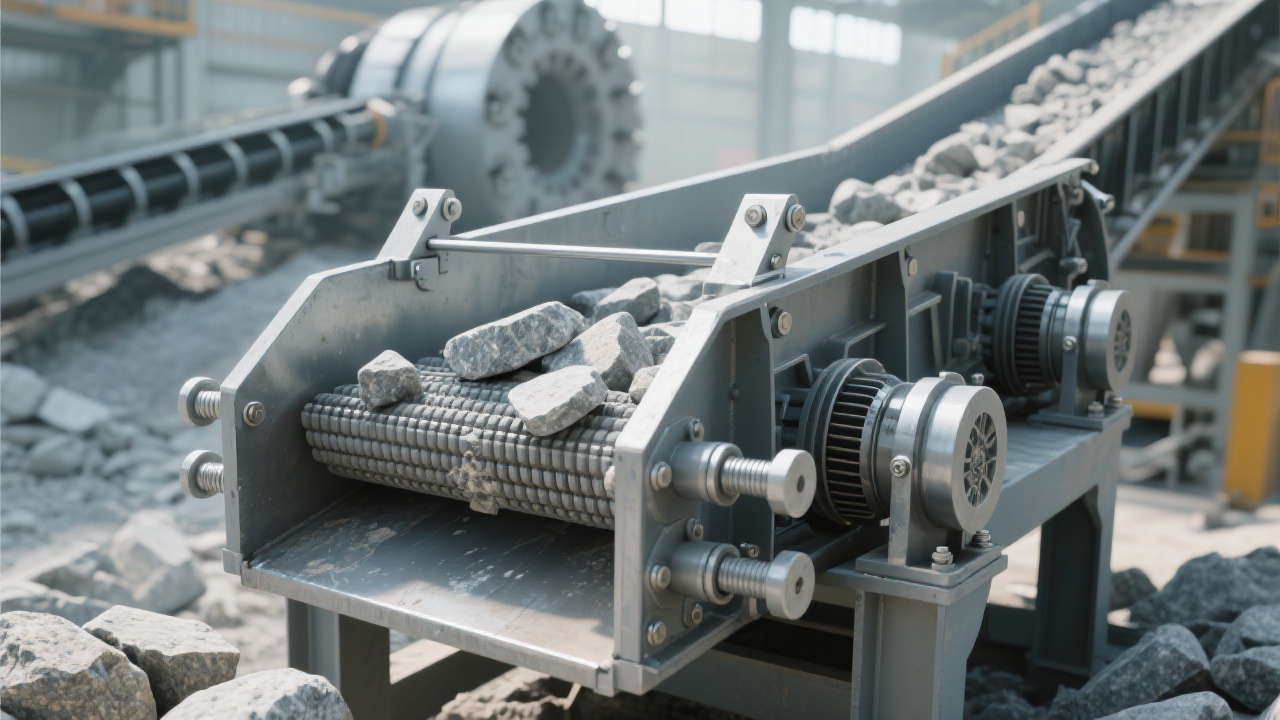

The NK Series isn’t just another mobile crusher—it’s engineered for flexibility. Each module (feed, crusher, conveyor, control cabin) is designed as a self-contained unit that can be connected via standardized interfaces. This means:

| Feature | Traditional Crusher | NK Series Modular |

|---|---|---|

| Assembly Time | 7–14 days | 1–2 days |

| Transport Complexity | High (specialized trucks required) | Low (standard trailers) |

| Maintenance Downtime | Average 3–5 hrs/day | Less than 1 hr/day |

These numbers aren’t hypothetical—they’re based on field data collected from 12 active sites over 18 months. And it’s not just efficiency: the NK Series delivers consistent throughput of up to 350 tons/hour across various rock types, thanks to its intelligent load-balancing system.

What sets NK apart is its built-in smart control system—no extra software or third-party integration needed. It monitors vibration levels, motor temperatures, and wear patterns in real time, alerting operators before issues escalate. In fact, users report a 40% drop in unexpected breakdowns after switching to NK.

And here’s something most competitors don’t talk about: the system learns your operation. After 30+ hours of use, it starts optimizing parameters automatically—like adjusting feed rate based on material hardness—to maximize output without sacrificing safety.

If you're managing multiple job sites, dealing with tight deadlines, or simply looking to cut down on setup costs—you might be overlooking the power of modularity. The NK Series doesn't just move faster; it adapts smarter, performs better, and pays for itself through fewer delays and lower maintenance.

See How NK Can Transform Your Workflow – Get the Free Technical Guide Now