In the quarrying industry, enhancing production efficiency while reducing costs is a top priority for every business. The NK series mobile crushing stations, developed by MiningAlliance with over 30 years of industry experience, offer an intelligent solution that is revolutionizing quarry operations. Let's delve into why the NK series is becoming the go - to choice for quarry owners.

Traditional fixed crushing stations often face several challenges. For instance, they require large - scale concrete foundations, which can be time - consuming and costly to install. In addition, they are difficult to relocate, making them less adaptable to changing quarry layouts. Moreover, their complex maintenance procedures can lead to long downtime periods.

The NK series directly tackles these issues. With its compact modular design, it doesn't need a large area for installation. The installation time is significantly reduced by up to 40% compared to traditional fixed crushing stations. This not only saves time but also reduces labor and material costs associated with the installation process. For example, a quarry in Australia was able to start production 2 weeks earlier after switching to the NK series, thanks to the shorter installation time.

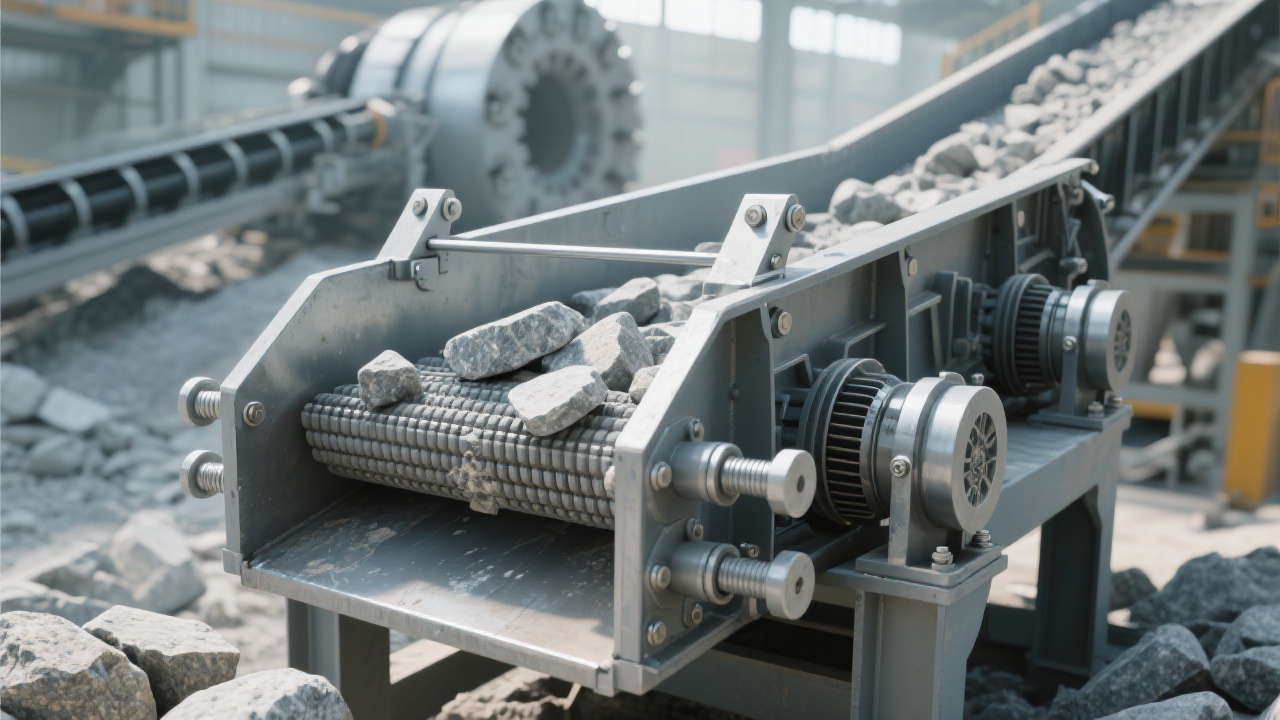

MiningAlliance's 30 - year technical expertise is reflected in the high - quality construction of the NK series. The high - capacity crushers used in the NK series are designed to withstand the toughest quarrying conditions. They are made from high - strength materials that ensure long - term durability and reliable performance. For example, the crushers can operate continuously for over 200 hours without major breakdowns, even in harsh environments with high dust and vibration levels.

This reliability translates into lower maintenance costs and less downtime. In fact, maintenance costs for the NK series are approximately 30% lower than those of traditional fixed crushing stations over a 5 - year period. This long - term cost - saving is a significant advantage for quarry operators.

The NK series is equipped with a PLC touch - screen intelligent control system. This system simplifies the operation process, allowing operators to monitor and control the entire crushing process with just a few touches on the screen. It provides real - time data on key parameters such as crusher speed, feed rate, and output size, enabling operators to make quick and accurate adjustments.

Moreover, the intelligent control system enhances safety. It has built - in safety features such as automatic shutdown in case of abnormal conditions, which reduces the risk of accidents. For example, in a quarry in South Africa, the intelligent control system detected an over - temperature issue in the crusher and automatically shut down the equipment, preventing a potential fire hazard.

Compared to traditional fixed crushing stations, the NK series offers unparalleled flexibility. It can be easily moved within the quarry, allowing it to be positioned closer to the source of raw materials. This reduces the transportation distance of the materials, saving on fuel and transportation costs. In some cases, transportation costs can be reduced by up to 25%.

Economically, the NK series provides a better return on investment. Its lower installation, maintenance, and transportation costs, combined with its high - efficiency production capabilities, ensure that every dollar invested yields visible returns. It truly redefines the efficiency standard of quarry operations.

Many quarries around the world have already experienced the benefits of the NK series. For example, a quarry in Canada increased its production capacity by 20% after adopting the NK series. Another quarry in Brazil saw a 15% reduction in overall operating costs within the first year of using the NK series.

| Quarry Location | Production Capacity Increase | Cost Reduction |

|---|---|---|

| Canada | 20% | N/A |

| Brazil | N/A | 15% |

These real - world examples demonstrate the tangible benefits that the NK series can bring to quarry operations.

The NK series mobile crushing stations offer a comprehensive solution for quarry operators looking to enhance production efficiency, reduce costs, and improve safety. Its unique design, high - quality construction, intelligent control system, and flexibility make it the ideal choice for modern quarry operations. By choosing the NK series, quarry operators can redefine their efficiency standards and ensure that every investment yields visible returns.

Do you have similar challenges in your quarry? Share your specific scenarios with us, and we'll send you 3 case studies of quarries that have successfully implemented the NK series. Click here to learn more about the NK series.