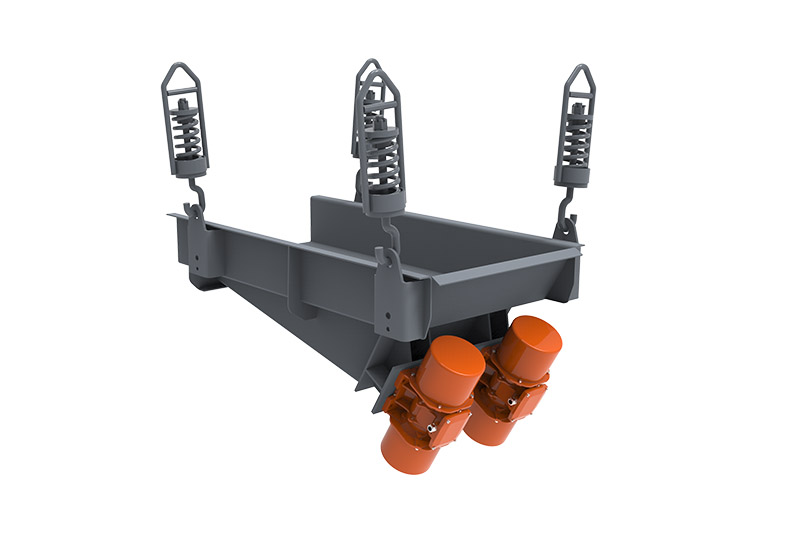

In the granite processing industry, the feeding stage is crucial for the overall efficiency of the crushing process. This article delves into the efficient feeding solutions in the granite processing flow, with a focus on the technical advantages of the GF Vibrating Feeder and its application effects in mobile crushing stations and semi - fixed crushing production lines.

The GF Vibrating Feeder boasts several remarkable technical features. Firstly, it has a large maximum feeding size. For instance, it can handle granite pieces up to 800mm in diameter, which is significantly larger than many traditional feeders in the market. This large feeding size allows for the direct input of large - sized granite materials, reducing the pre - processing steps and saving time and cost.

Secondly, its high processing capacity is another highlight. The feeder can process up to 500 tons of granite per hour, ensuring a continuous and stable supply of materials for the subsequent crushing process. This high - throughput capacity is especially beneficial for large - scale granite processing plants.

The unique double - layer screening structure is also a key advantage. This structure can effectively separate fine materials from large - sized materials at the feeding stage. Approximately 30% of the fine materials can be screened out in advance, which not only reduces the load on the subsequent crushers but also improves the overall crushing efficiency.

The adjustment of the exciting force of the GF Vibrating Feeder is a core technology for achieving precise feeding and stable material transportation. The principle is based on the change of the relative position of the eccentric blocks in the vibration motor. By adjusting the angle between the eccentric blocks, the magnitude of the exciting force can be changed.

In practical operation, operators can adjust the exciting force according to the characteristics of the granite materials and the requirements of the subsequent crushing process. For example, when processing hard granite, a larger exciting force can be set to ensure the smooth transportation of materials. Through this adjustment, the feeder can achieve an error of less than ±5% in material feeding, which greatly optimizes the subsequent crushing process.

Let's look at some typical production cases. In a small - scale granite processing plant, after using the GF Vibrating Feeder, the production efficiency increased by 20%. The plant was able to process an additional 50 tons of granite per day, which directly translated into an annual increase in revenue of approximately $200,000.

In a large - scale granite processing project, the use of the GF Vibrating Feeder reduced the equipment wear of the subsequent crushers by 30%. This not only extended the service life of the crushers but also saved a large amount of maintenance costs. The project saved approximately $500,000 in maintenance costs per year.

When selecting the GF Vibrating Feeder, factors such as the production scale, material characteristics, and subsequent process requirements should be considered. For small - scale plants, a feeder with a processing capacity of 100 - 200 tons per hour may be sufficient, while large - scale plants may need a feeder with a capacity of over 500 tons per hour.

In terms of maintenance, regular inspection of the vibration motor, screening structure, and connection parts is necessary. It is recommended to conduct a comprehensive inspection every 500 operating hours and replace worn - out parts in time.

The GF Vibrating Feeder offers unique technical advantages and significant economic benefits in granite processing. Its application can greatly improve the efficiency of the crushing process, reduce equipment wear, and optimize the overall production process. If you are looking for a high - performance vibrating feeder for your granite processing business, don't miss the GF Vibrating Feeder. Learn More about GF Vibrating Feeder

| Question | Answer |

|---|---|

| What is the maximum feeding size of the GF Vibrating Feeder? | The maximum feeding size can reach 800mm. |

| How to adjust the exciting force? | The exciting force can be adjusted by changing the angle between the eccentric blocks in the vibration motor. |

If you have any other questions or comments about the GF Vibrating Feeder, please feel free to leave a message below. We will respond to you as soon as possible.