In the dynamic realm of material handling, efficiency stands as the cornerstone of success. Delays, bottlenecks, and sub - optimal equipment can significantly impede production processes, leading to increased costs and reduced competitiveness. Amidst these challenges, the GF Vibrating Feeder emerges as a game - changer, offering a solution that revolutionizes material feeding across diverse production environments.

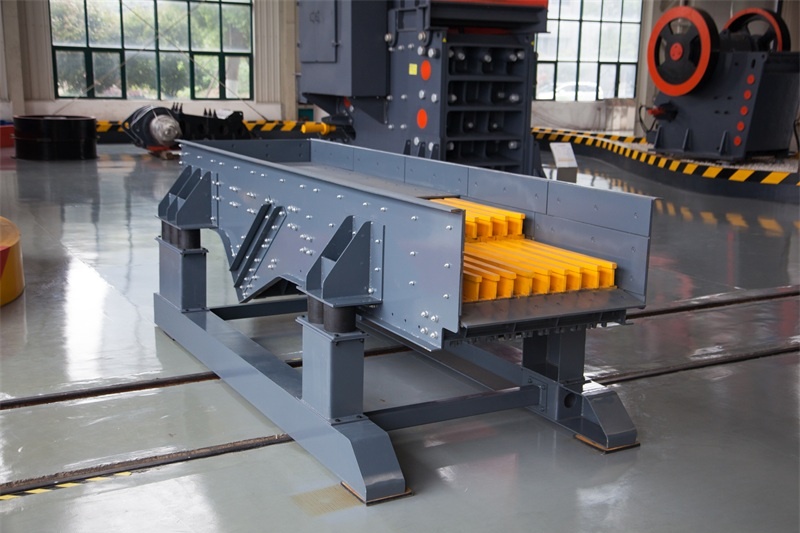

The GF Vibrating Feeder is a high - efficiency primary feeding device engineered to meet the demanding requirements of modern industries. It is highly adaptable and can be seamlessly integrated with mobile crushing stations and other production setups, providing a reliable and continuous flow of materials.

One of the most striking features of the GF Vibrating Feeder is its remarkable efficiency. With an impressive feed size of up to 700 millimeters and a processing capacity ranging from 280 to 450 tons per hour, it outperforms many traditional feeding equipment. To put this into perspective, traditional feeders may only handle 150 - 200 tons per hour under similar conditions. This significant increase in throughput translates into faster production cycles and higher overall productivity.

| Equipment Type | Feed Size (mm) | Processing Capacity (tons/hour) |

|---|---|---|

| GF Vibrating Feeder | Up to 700 | 280 - 450 |

| Traditional Feeder | Up to 500 | 150 - 200 |

The GF Vibrating Feeder showcases its multi - scenario adaptability through its wide range of applicable materials. It can handle various types of stones, including granite, limestone, basalt, and gravel. Whether it's for a quarry operation, a construction site, or a recycling plant, the GF Vibrating Feeder can efficiently process different materials, making it a versatile choice for diverse industries.

At the heart of the GF Vibrating Feeder lies its state - of - the - art vibration motor. This motor serves as the reliable vibration source, providing a stable and consistent flow of materials. The vibration frequency and amplitude can be precisely adjusted to meet the specific requirements of different materials and production processes. This not only ensures efficient material handling but also reduces wear and tear on the equipment, extending its service life.

To further illustrate the effectiveness of the GF Vibrating Feeder, let's look at some real - world customer cases. A large - scale quarry in Europe was facing challenges with slow material feeding and frequent equipment breakdowns. After installing the GF Vibrating Feeder, they witnessed a 30% increase in production efficiency. The stable material flow also reduced the downtime of the subsequent crushing equipment, resulting in significant cost savings.

In conclusion, the GF Vibrating Feeder is a powerful and versatile solution for material feeding in different production environments. Its high efficiency, wide material compatibility, and advanced vibration technology make it a top choice for industries seeking to optimize their production processes. The GF Vibrating Feeder opens a new era of efficient material handling, solves your material feeding problems, and enhances production efficiency. Welcome to learn more and consult!