In the modern industrial landscape, the efficiency of material handling is a critical factor that directly impacts production costs and overall productivity. Many businesses in the mining, construction, and recycling industries face challenges in achieving high - efficiency material conveyance. Slow feeding, inconsistent material flow, and limited adaptability to different materials and environments often lead to bottlenecks in the production process. However, the GF Vibrating Feeder emerges as the optimal solution to these long - standing problems.

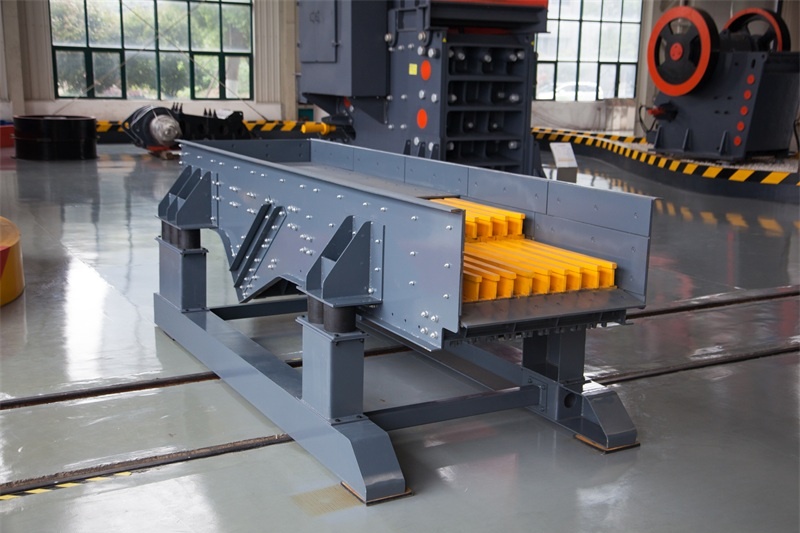

The GF Vibrating Feeder is designed as a high - performance primary feeding device. It is suitable for a wide range of scenarios, including mobile crushing stations, semi - fixed crushing production lines, and small storage bins. Its versatility makes it an indispensable tool in various industrial settings. For instance, in a mobile crushing operation, the feeder can be easily integrated with the crushing equipment, ensuring a continuous and stable supply of materials.

When it comes to work efficiency, the GF Vibrating Feeder truly shines. It can handle materials with a maximum feed size of up to 700 millimeters. This large feed size allows it to process bulkier materials without pre - crushing, saving time and energy. In terms of processing capacity, it can achieve a throughput of 280 - 450 tons per hour. Compared with traditional feeding equipment, which may have a processing capacity of only 100 - 200 tons per hour, the GF Vibrating Feeder significantly outperforms its counterparts, enabling businesses to increase their production output substantially.

Another remarkable feature of the GF Vibrating Feeder is its ability to adapt to a variety of stones and materials. It can handle common stones such as limestone, granite, basalt, and sandstone. Whether it is for the production of aggregates for construction or the processing of minerals in mining operations, the feeder can perform effectively. This wide range of applicability means that businesses do not need to invest in multiple feeding devices for different materials, reducing equipment costs and simplifying the production process.

The GF Vibrating Feeder uses a vibration motor as its vibration source. This design offers several technical advantages. First of all, the vibration motor provides a stable and uniform vibration, which ensures a smooth and consistent flow of materials. Unlike some traditional feeders that may experience uneven material flow due to unstable vibration, the GF Vibrating Feeder can maintain a constant feeding rate, improving the overall efficiency of the production line. Secondly, the vibration motor is highly energy - efficient, consuming less power compared to other vibration mechanisms, which helps businesses save on energy costs in the long run.

A mining company in South America was struggling with low - efficiency material feeding in its crushing plant. The traditional feeder they used could not handle the large - size ores efficiently, resulting in frequent blockages and slow production. After installing the GF Vibrating Feeder, the situation improved significantly. The feeder's large feed size and high - capacity processing allowed it to handle the ores smoothly. The company reported a 30% increase in production output within the first month of using the GF Vibrating Feeder, along with a reduction in maintenance costs due to fewer blockages.

In conclusion, the GF Vibrating Feeder is a game - changer in the field of material handling. It can effectively solve the problems of low efficiency in material transportation, bringing significant improvements in production efficiency and cost savings for businesses. If you are looking for a reliable and efficient solution to enhance your material handling process, we invite you to contact us for more information or to arrange a trial of the GF Vibrating Feeder. Take the first step towards a more productive future today!