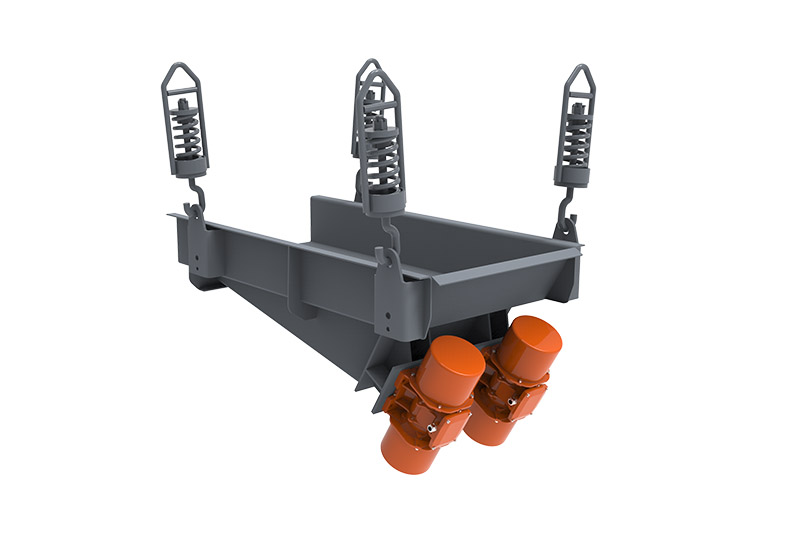

GF vibrating feeder is specifically designed for the processing of granite and various hard ores. In the granite processing industry, efficient feeding equipment is crucial for the smooth operation of the entire production line. The GF vibrating feeder stands out with its remarkable features and advantages.

One of the key highlights of the GF vibrating feeder is its large feeding size. It can handle a maximum feed size of up to 700 millimeters. This large feeding capacity allows it to directly process large - sized hard stones, reducing the pre - processing steps. With a high processing capacity ranging from 280 to 450 tons per hour, it can significantly enhance the production efficiency of the crushing line. For example, in a large - scale granite quarry, using the GF vibrating feeder can increase the daily production by about 30% compared to traditional feeders.

The GF vibrating feeder is equipped with a unique double - layer screening structure. This structure can effectively separate fine materials from large - sized stones during the feeding process. The fine materials can directly enter the subsequent process without passing through the crusher, which not only optimizes the crushing process but also reduces the wear and tear of the crusher. According to practical data, this can reduce the crusher's wear by about 20% and extend its service life.

Another significant advantage is the exciting force adjustment technology. Operators can adjust the exciting force according to the characteristics of different materials and the requirements of the production line. This ensures accurate feeding and improves the overall stability of the production line. In a mobile crushing station, the ability to adjust the exciting force allows the GF vibrating feeder to adapt to different working conditions, improving the flexibility and efficiency of the entire production system.

The GF vibrating feeder has excellent performance in both mobile crushing stations and semi - fixed crushing production lines. In mobile crushing stations, its compact structure and high - efficiency feeding function make it an ideal choice for on - site processing. In semi - fixed production lines, it can provide a stable and continuous feeding source, ensuring the long - term and stable operation of the production line. For instance, in a semi - fixed granite processing plant, the GF vibrating feeder has been running stably for over 2 years, with a reliability rate of over 95%.

When selecting the GF vibrating feeder, factors such as the type of material, production scale, and feeding requirements should be considered. Regular maintenance is also essential to ensure its long - term stable operation. For example, lubricating the bearings every 500 hours of operation and checking the screening structure every 1000 hours can effectively prevent equipment failures.

| Question | Answer |

|---|---|

| Can the GF vibrating feeder handle other hard materials besides granite? | Yes, it is designed to process various hard ores, such as basalt, quartzite, etc. |

| How difficult is it to adjust the exciting force? | It is relatively easy. The feeder is equipped with a user - friendly control system that allows operators to adjust the exciting force according to the instructions. |

We encourage you to leave your comments and questions in the section below. Our team will be happy to answer them and engage in further discussions with you.

Explore the GF Vibrating Feeder for Your Granite Processing Needs