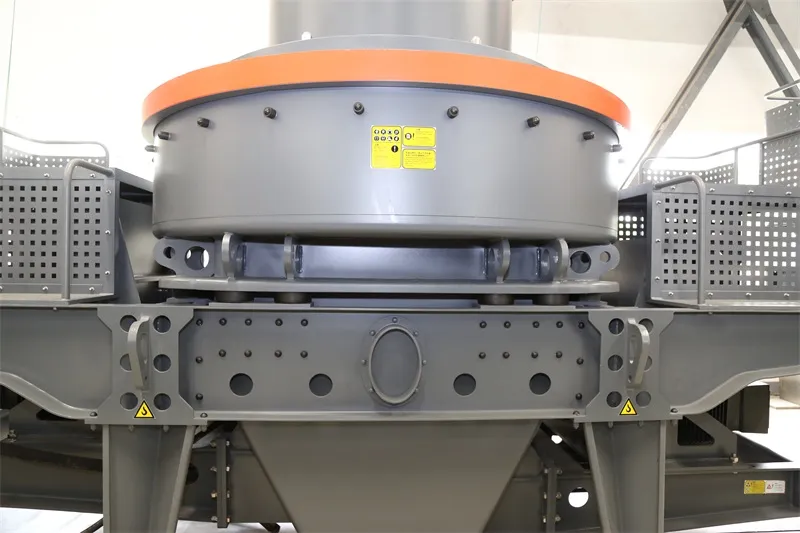

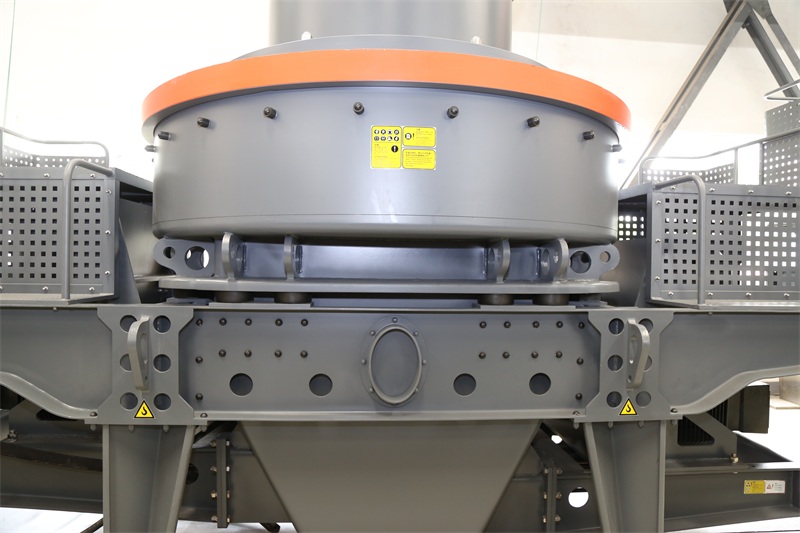

The mining and construction sectors continuously demand more efficient and cost-effective sand making solutions. Conventional sand making machines often wrestle with challenges such as low throughput, excessive wear on components, and high operational costs, hindering productivity and profitability. Addressing these persistent pain points, Zhengzhou KNL Machinery has engineered the 4th Generation VSI Sand Making Machine featuring an innovative dual feed system that revolutionizes the crushing workflow.

The proprietary design integrates both central and side feed inlets, a breakthrough compared to traditional single-feed VSI crushers. This configuration specifically addresses the need for handling varied material properties—like hardness and moisture content—by optimizing the feed distribution and particle acceleration inside the crushing chamber.

By synergizing the roles of the central inlet—focused on high velocity particle acceleration—and the side inlet—allowing additional material flow that optimizes particle shaping, the machine achieves an improved crushing profile. This results in enhanced particle cubicity, superior sand quality, and more efficient material circulation within the crushing cavity.

A redesigned crushing chamber complements the dual feed system by minimizing turbulent flow zones and abrasive contacts that usually accelerate wear on critical components. Advanced wear-resistant materials and an intelligently contoured cavity ensure uniform particle impact distribution.

| Key Metrics | Traditional VSI Machine | KNL 4th Gen Dual Feed VSI |

|---|---|---|

| Throughput (tons/hour) | ~400 | 520+ |

| Efficiency Improvement | Baseline | +30% |

| Wear Part Life Extension | Average 3 Months | Up to 6 Months |

| Operational Cost Reduction | - | ~15% |

The practical outcome is dual-fold: it reduces downtime for maintenance and material replacement while simultaneously driving consistent production capacity. Operators report smoother operations with fewer interruptions, translating to a more predictable and stable return on investment.

Case studies from mining enterprises in Southeast Asia highlight tangible benefits. One quarry operator increased their sand output by over 30% while reducing wear part expenses by nearly 40% annually. These results were achieved within the first operational quarter after implementing the dual feed VSI system.

This not only boosts operational throughput but also improves sand quality metrics, crucial for concrete manufacturing and infrastructure projects demanding stringent grading and shape standards. The overarching effect is enabling businesses to embrace high-efficiency production sustainably.

Embracing advanced designs like the KNL fourth generation VSI with dual feed technology signals the dawn of a more productive era in sand making operations. It empowers operators to unlock beyond-standard throughput of 520 tons per hour, reduce maintenance cycles, and drive down operating expenses.

For mining and construction enterprises aiming to stay competitive, this innovation offers more than an equipment upgrade—it’s a strategic investment that creates stable long-term value and operational resilience.