In the dynamic world of mining and construction, adapting to changing production demands is crucial for businesses to stay competitive. One company, facing significant production challenges, found a game - changing solution in MiningAlliance's NK series mobile crushing stations. This case study delves into how the company transformed its production line through the flexible assembly of these innovative machines.

The client, a medium - sized mining and aggregates company, was struggling with high installation costs, long setup times, and limited flexibility in their production line. Their existing fixed crushing equipment required extensive concrete foundations and time - consuming installation processes. Moreover, any changes to the production layout meant significant downtime and high costs. The company needed a solution that could reduce installation time and costs while allowing for quick adjustments to the production line.

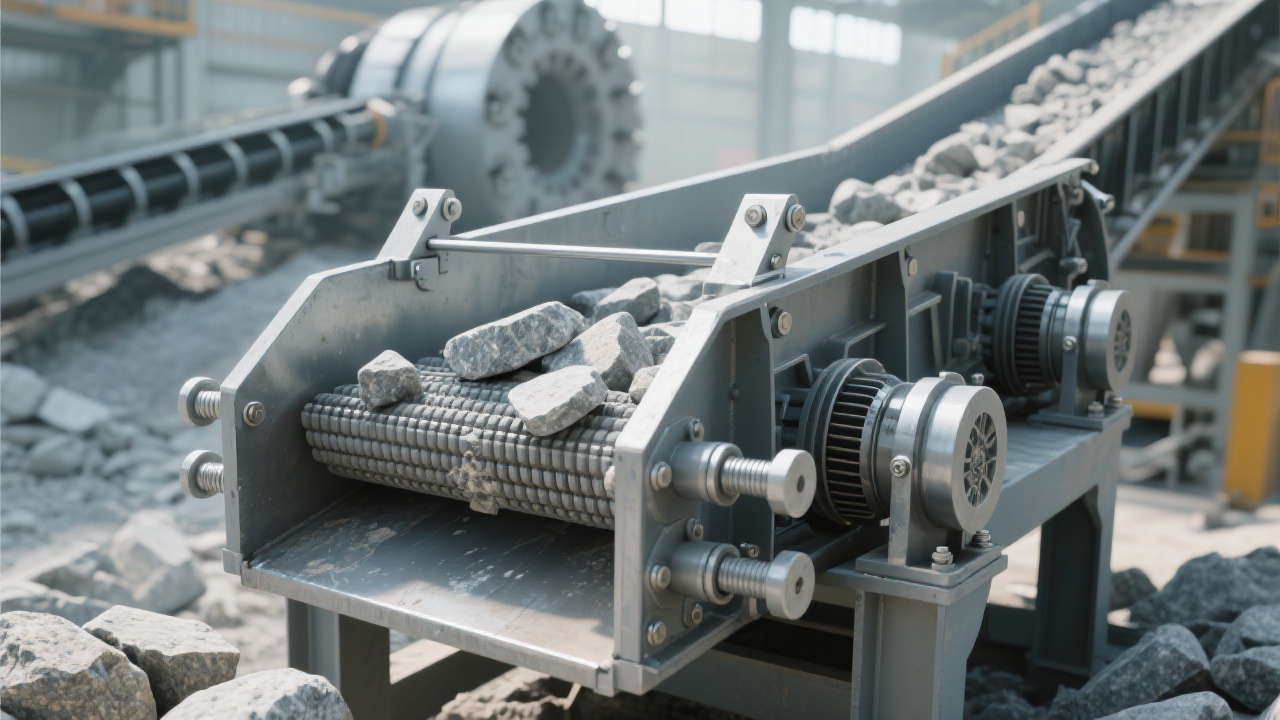

MiningAlliance's NK series mobile crushing stations offered a comprehensive solution to the client's problems. These stations are equipped with several key features that make them stand out in the market.

The NK series features a modular trailer design, which allows for easy transportation and on - site assembly. The modules can be quickly connected, reducing the installation time from weeks to just a few days. For example, in the client's case, the installation of the NK series mobile crushing station was completed in only 3 days, compared to the previous 2 - week installation time for their fixed equipment.

One of the most significant advantages of the NK series is its ability to operate without a concrete foundation. This not only saves on the cost of concrete but also eliminates the time - consuming process of pouring and curing concrete. The station uses adjustable support legs to ensure stability, which can be quickly set up on various terrains. The client estimated that they saved approximately $50,000 in concrete and foundation construction costs by choosing the NK series.

The intelligent control system of the NK series enables real - time monitoring and adjustment of the crushing process. Operators can remotely control the equipment, adjust parameters such as feed rate and crushing ratio, and receive instant feedback on the equipment's performance. This system has improved the overall efficiency of the production line, reducing human error and increasing productivity. In the client's operation, the intelligent control system helped increase the production capacity by 20% compared to their previous setup.

The client took full advantage of the flexible assembly feature of the NK series to quickly adjust their production line. When there was a change in the demand for different aggregate sizes, they were able to reconfigure the crushing station within a day. This flexibility allowed them to respond promptly to market changes and increase their market share.

To further illustrate the superiority of the NK series, a comparison was made with other similar products in the market. The following table shows the key differences:

| Features | NK Series Mobile Crushing Stations | Competitor Products |

|---|---|---|

| Installation Time | 3 days | 1 - 2 weeks |

| Installation Cost | $50,000 savings | Higher due to concrete foundation |

| Production Capacity Increase | 20% | 10% on average |

| Flexibility for Line Adjustment | Can be reconfigured in 1 day | Requires 3 - 5 days |

The NK series mobile crushing stations have proven to be a game - changer for the client, enabling them to overcome production challenges, reduce costs, and increase productivity. The flexible assembly feature, combined with advanced technology and intelligent control, provides a sustainable solution for businesses in the mining and construction industries. If you are facing similar production problems, why not explore the potential of the NK series mobile crushing stations? Click here to learn more and request a free trial.

Do you have any production problems in your business? Share your experiences in the comments below, and we'll send you 3 case studies of similar solutions from the same industry.