In the mineral extraction and construction sectors, operational agility and equipment reliability have become non-negotiable. The NK Series Mobile Crushing Plant, forged over three decades of engineering experience, emerges as a solution designed to meet these industry demands. Seamlessly combining robust modularity with intelligent automation, this crushing plant redefines efficiency, ease of deployment, and cost-effectiveness.

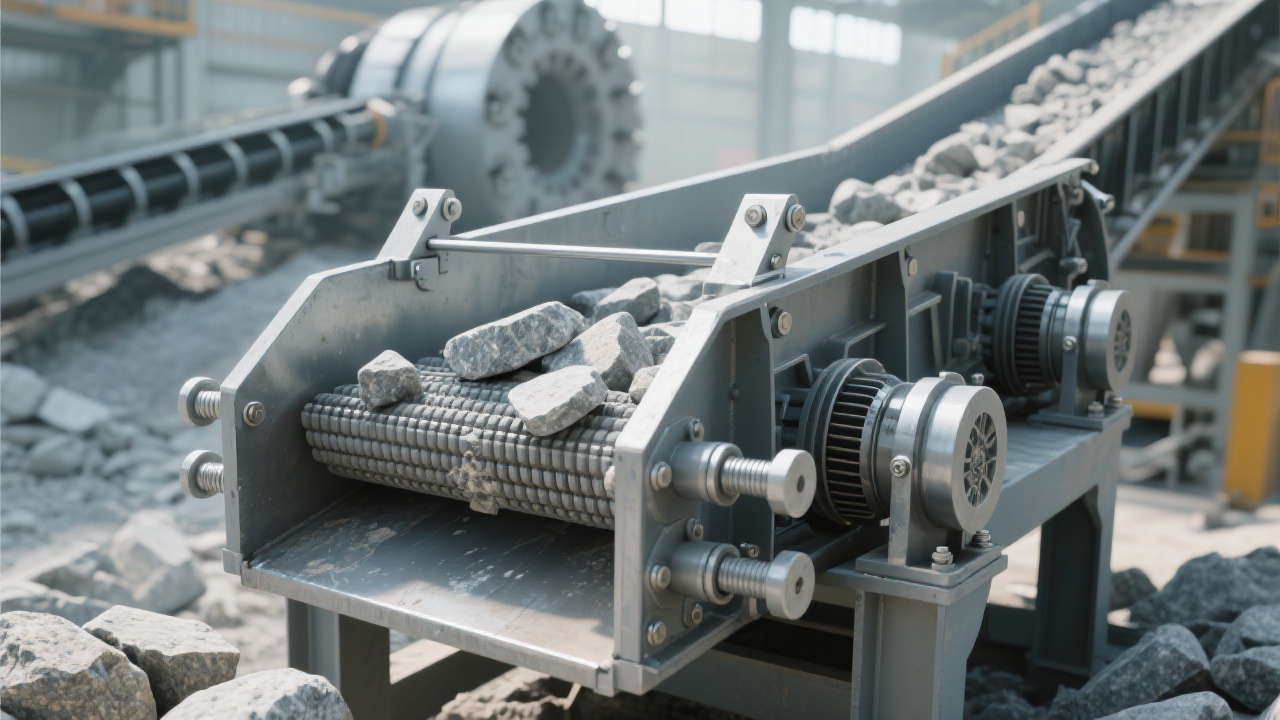

One of the fundamental challenges in crusher deployment has been balancing machine stability with transport flexibility. The NK Series addresses this through a compact modular structure that not only stabilizes the crushing components but also enables rapid disassembly and transportation.

Industry data show that modular mobile units reduce installation time by up to 40% compared to traditional fixed stations. This translates to minimized downtime and accelerated project kickoffs, especially critical in sites where time-to-production dictates profitability.

Moreover, the NK Series' module-based chassis design permits swift transition between job sites without specialized equipment, enhancing operational flexibility essential for mining firms handling multiple pits or urban construction companies managing disparate locations.

Contrary to conventional expectations, the NK Series eliminates the need for a poured concrete foundation. By employing a robust steel frame foundation engineered to withstand heavy-duty vibrations and load stresses, operators can install the plant directly on leveled ground.

This design breakthrough shortens lead times by obviating complex civil engineering, resulting in up to 35% reduction in upfront setup costs and freeing capital for other critical operations. Without the usual curing times and preparatory works, production can commence days earlier — a decisive competitive advantage.

Automation has become synonymous with operational excellence, and the NK Series incorporates a state-of-the-art Programmable Logic Controller (PLC) system. This intelligent control synchronizes the crushing and screening processes for optimal throughput and energy efficiency.

The PLC system offers remote monitoring capabilities with real-time diagnostics, allowing operators to adjust parameters, detect material blockages, and schedule maintenance proactively. Case studies reveal that downtime decreases by approximately 22% once integrated PLC controls facilitate predictive maintenance.

This technology is particularly beneficial in environments with fluctuating feed compositions or demanding regulatory compliance on emissions and noise, where precision control directly impacts profitability and environmental responsibility.

| Criteria | Traditional Fixed Stations | NK Series Mobile Crushing Plant |

|---|---|---|

| Installation Time | Weeks to Months (foundation + setup) | Hours to Days (no foundation required) |

| Mobility | Limited, fixed | High, rapid site redeployment |

| Operational Cost | Higher (infrastructure + maintenance) | Lower (modular adjustments + predictive maintenance) |

| Control System | Manual or semi-automated | Full PLC Intelligent Automation |

| Flexibility in Application | Less adaptable | Wide-ranging (mining, demolition, construction debris) |

At a prominent quarry site in Southeast Asia, deploying the NK Series led to a 28% increase in throughput with simultaneous 18% reduction in fuel consumption. The mobile nature allowed the operator to chase the resource face efficiently, avoiding expensive material stockpiling.

In urban demolition projects in Europe, rapid setup without foundation work enabled seamless integration into constrained spaces, effectively reducing project turnover time by almost 25%. Additionally, the intelligent control system allowed precise sorting and screening of mixed construction waste, enhancing recycling rates.

Reliability is the cornerstone of the NK Series. Over three decades, continuous R&D and field feedback have refined the system to withstand harsh conditions, ranging from abrasive mining substrates to humid coastal environments. Utilizing premium wear-resistant materials and precision engineering, the plant promises minimization of unplanned shutdowns and maintenance intervals extended by up to 20%.

The NK Series is not just machinery; it is an investment in dependable productivity growth — making every unit a powerful driver of your operational success.